Tired of soggy plates and rising waste? Bamboo may be your answer.

Bamboo pulp fiber plates are stronger, safer, and more sustainable than traditional paper plates.

Let’s dig deeper to find out which plate truly serves better.

What are the differences between bamboo pulp and paper plates?

Pressed bamboo sheets or bamboo pulp fiber? Know the difference before you choose.

Bamboo pulp fiber is more eco-friendly and performs better than traditional paper plates.

Understanding Two Types of Bamboo Plates

Not all bamboo plates are made the same. Many buyers ask me about the difference between pressed bamboo sheet plates and bamboo pulp fiber plates. These are two very different products in both manufacturing and application.

Pressed Bamboo Sheet Plates

Pressed bamboo sheet plates are made by rotary-cutting bamboo tubes into thin bamboo veneers about 0.3 mm thick. These veneers are dried, laid out in three crosswise layers, and then hot-pressed and cold-pressed to form the final product.

But the process has strict raw material requirements. It needs large, round bamboo stalks. From every 10 bamboo poles, only 1–2 are usable, and even then, only about 1 meter per stalk can be used. The utilization rate is low, around 30%, because most of the bamboo is not suitable for rotary cutting.

This makes supply very limited, and the market is often undersupplied. Still, the final product is premium in texture and strength. These plates are often found in high-end dining or gift packaging. They come in round or square shapes, with sizes such as 7", 9", 10", and 11", and cost around $0.28–$0.42 per unit.

Bamboo Pulp Fiber Plates

This article focuses on bamboo pulp fiber plates, which are different in every way.

They are made through a wet molding process, which borrows from traditional paper pulp forming. The steps include:

- Pulping the bamboo using refined equipment

- Adding eco-safe additives

- Using molds to shape plates

- Cold pressing to set the form

- Hot pressing to finalize strength and texture

This method allows consistent quality and mass production. Bamboo pulp plates are common in many settings and come in:

- 6", 7", 9", and 10" sizes

- Single-compartment and three-compartment formats

They closely match paper pulp plates in price and application but outperform in durability, compostability, and appearance.

That’s why the rest of this article focuses on comparing bamboo pulp fiber plates and traditional paper plates—since they are the true alternatives for daily and commercial use.

| Plate Type | Material Source | Main Process | Market Status | Price Range (USD) | Mass Production? |

|---|---|---|---|---|---|

| Pressed Bamboo Sheet Plate | Rotary-cut bamboo stalks | Veneer pressing (hot + cold) | High demand, low supply | $0.28 – $0.42 | ❌ No |

| Bamboo Pulp Fiber Plate | Bamboo pulp fiber | Wet molding (pulp-forming) | Widely available | $0.03 – $0.07 | ✅ Yes |

| Paper Plate | Wood pulp + coating | Pressing + chemical coating | Widely available | $0.014 – $0.028 | ✅ Yes |

So if you’re looking for a scalable, affordable, and eco-conscious option, bamboo pulp fiber plates are the logical replacement for traditional paper plates.

Are bamboo plates more environmentally friendly?

Plastic bans are rising. Choosing the right eco product matters more than ever.

Bamboo pulp plates have a lower carbon footprint and decompose faster than paper plates.

Raw materials and biodegradability

Bamboo is one of the fastest-growing plants in the world. In the right conditions, it can grow up to 90 cm per day. This speed gives bamboo a big edge over trees used for paper. Bamboo needs no replanting after harvesting. Its root system stays in place and regenerates naturally.

On the other hand, paper plates are made from trees that take years to grow. This leads to higher deforestation rates and larger land use. Also, many paper plates are coated with plastic, which slows down their ability to degrade and makes them hard to recycle.

Emission and energy comparison

Here’s how the production impact stacks up:

| Impact Category | Bamboo Pulp Plates | Paper Plates |

|---|---|---|

| CO₂ Emissions (kg/ton) | ~450 | ~900 |

| Energy Use | Moderate (steam pressure) | High (bleaching, drying) |

| Water Use | Lower | Higher |

| Compost Time | 45–60 days | 120–180 days (if coated) |

I’ve visited our bamboo forests in Fujian and Yunnan. These regions provide raw bamboo stalks sustainably harvested for pulp. Compared to wood pulp factories, our emissions are cut in half, and there’s no bleach in our process.

Do bamboo plates perform better during use?

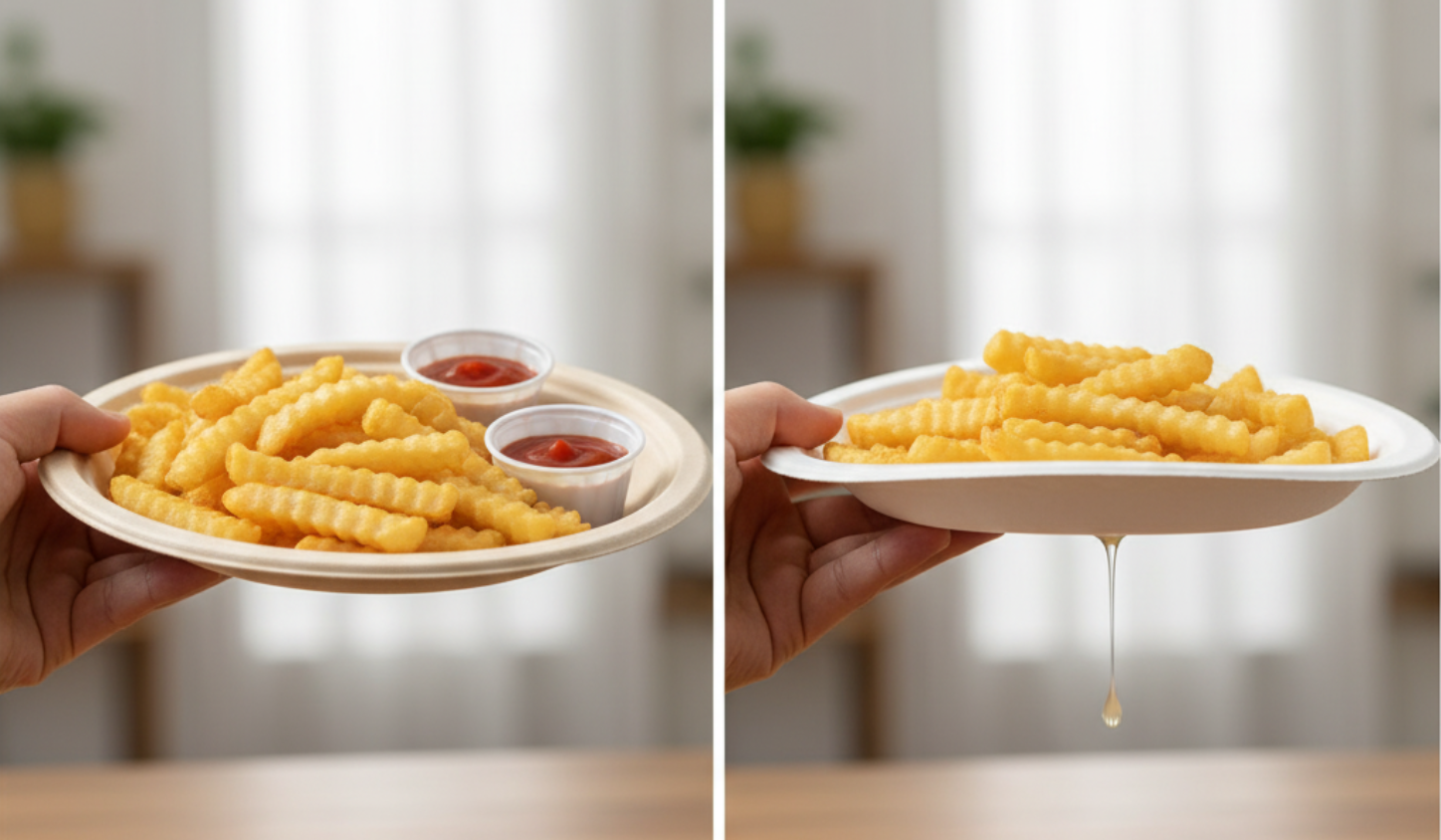

Nobody wants leaks or sagging during meals. Bamboo stands strong when paper gives up.

Bamboo plates are more durable and resistant to water and oil than paper plates.

Strength and performance in real use

Bamboo fiber plates are molded at high temperatures and under pressure. This makes them sturdy, smooth, and naturally oil- and water-resistant. I’ve tested our plates personally at events—no soft bottoms, no collapsing under a heavy burger.

Paper plates absorb liquid fast. After a few minutes, they sag and sometimes fall apart. Most need double stacking or a plastic lining. In hot food service, especially for catering, this becomes a huge issue. No one wants soup or curry soaking through to the guest’s hands.

Natural antibacterial qualities

Bamboo also has natural antibacterial agents. These reduce the risk of cross-contamination. Here’s a performance breakdown:

| Test Condition | Bamboo Plate | Paper Plate |

|---|---|---|

| Holds hot soup | ✅ Yes, no warping | ❌ No, becomes soggy |

| Grease from burgers | ✅ No stains or leaks | ❌ Leaks in minutes |

| Reheating in microwave | ✅ Safe for short use | ❌ Risky if coated |

| Stackability | ✅ Easy to store | ✅ But less efficient |

I’ve had caterers tell me our plates made cleanup easier and reduced complaints. In high-end dining, a strong plate boosts brand image.

Are bamboo plates safer for health?

Health should not be optional. Your tableware touches your food.

Bamboo plates are chemical-free and safe for hot, oily, or acidic foods.

Chemical safety in daily use

Bamboo pulp plates are free from BPA, PFAS, and heavy metals. We don’t use bleach or coatings. This means no chemicals leach into food, even when serving acidic or oily dishes. This is critical for eco-conscious restaurants and schools.

In contrast, many paper plates use coatings. Some use polyethylene (PE) or wax to make them water-resistant. These materials can melt or leach toxins when exposed to heat.

I’ve worked with clients in California and Australia who demanded FDA and LFGB certifications. Without them, they couldn’t use paper plates at all. With bamboo, we meet those standards and more.

| Food Safety Aspect | Bamboo Pulp Plate | Paper Plate |

|---|---|---|

| BPA/PFAS Free | ✅ Yes | ❌ Not always |

| Microwave Safe | ✅ Short bursts | ❌ Risk with coatings |

| Odor and Taste | ✅ Neutral | ❌ Can affect flavor |

| Certifications Available | ✅ FDA, LFGB, BPI | ✅ But less consistent |

Are bamboo plates worth the price?

Cost matters—but so does long-term value and user experience.

Bamboo plates cost slightly more upfront but reduce waste and customer dissatisfaction.

Cost vs. value breakdown

Yes, bamboo plates can cost 10–30% more per unit than basic paper plates. But that’s only part of the picture. Bamboo plates are stronger. You don’t need to double-stack them. There’s less leakage, less mess, and better presentation.

Let’s look at a real price comparison using a 7-inch plate:

| Plate Type | Price (USD) |

|---|---|

| Paper Plate | $0.014 |

| Bamboo Plate | $0.028 |

Bamboo costs about double, but many of our clients end up using fewer plates because of better performance. For example, with paper plates, they often need to double-stack or deal with breakage, leading to more waste and higher hidden costs.

Over 10,000 plates, that’s a jump from $140 to $280, but if you only need 7,000 bamboo plates to do the same job, the cost becomes almost equal. On top of that, you boost your brand image and customer satisfaction.

| Category | Bamboo Plates | Paper Plates |

|---|---|---|

| Unit Cost (7-inch) | $0.028 | $0.014 |

| Double Stacking Needed | ❌ No | ✅ Often |

| Guest Satisfaction | ✅ High | ❌ Lower |

| Post-event Waste Volume | Low | High |

When buying wholesale, small differences in plate quality lead to big differences in value.

Where do bamboo plates fit best in the market?

Different buyers have different needs. Choosing smartly improves brand value.

Bamboo plates are ideal for eco-conscious brands, events, and premium services.

Application and branding benefits

Bamboo plates work well in premium restaurants, organic food trucks, boutique cafes, wedding caterers, and zero-waste shops. Many large brands are moving away from paper and plastic. They now want eco packaging with a story.

PANABAM works with clients in the U.S., Australia, and Germany. We offer custom logo embossing, size options, and environmental certifications like FSC, BPI, and FDA. These help our B2B clients meet local compliance rules and strengthen brand trust.

| Market Segment | Bamboo Plates Fit? | Paper Plates Fit? |

|---|---|---|

| Zero-Waste Events | ✅ Yes | ❌ Not preferred |

| Government Food Services | ✅ Meets plastic bans | ❌ Limited use |

| Budget Chains | ❌ Higher cost | ✅ Cheaper option |

| Premium Catering | ✅ Boosts image | ❌ Not durable enough |

| Amazon/Etsy Sellers | ✅ Strong branding potential | ❌ Weak differentiation |

Conclusion

Bamboo plates beat paper ones in eco-friendliness, strength, safety, and long-term value.

Frequently Asked Questions

1. Do bamboo plates hold bacteria?

No, they don’t. Bamboo has natural antibacterial properties, which help prevent bacterial growth on the surface. I’ve tested our plates after multiple uses in humid conditions, and they remained safe and clean. For single-use bamboo pulp plates, bacteria buildup is not a concern, as they are designed to be used once and composted.

2. What is the best alternative to paper plates?

In my opinion, bamboo pulp fiber plates are the best alternative. They’re biodegradable, stronger, safer for food, and perform better with liquids or heat. Compared to paper plates with plastic coatings, bamboo is more eco-friendly and meets stricter sustainability regulations in countries like the U.S. and EU.

3. Are bamboo disposable plates good?

Yes, absolutely. I manufacture them myself, and I use them personally at events. They’re sturdy, leak-resistant, and heat-safe. They don’t get soggy like paper or break like plastic. Plus, they look great and leave a good impression on customers or guests.

4. Can bamboo plates go in a dishwasher?

It depends on the type. Pressed bamboo sheet plates can sometimes be washed once or twice, but bamboo pulp fiber plates are not dishwasher-safe. They are designed for single use. If you want reusability, go for bamboo wood plates, not molded pulp versions.

5. Do bamboo plates go mouldy?

Not if stored correctly. Our disposable bamboo pulp plates are fully dried and compressed during production. As long as you keep them in a cool, dry place, they won’t grow mold. I store mine in a carton box with a sealed liner to avoid moisture during shipment and warehousing.

6. Why is bamboo better than paper?

Because it grows faster, uses less land, and decomposes naturally. Bamboo regenerates in weeks without replanting, while trees take decades. In production, bamboo pulp plates also require less energy and water. Plus, they don’t need plastic coatings to perform well with liquids or heat.

7. How long do bamboo plates last?

For disposable use, they’re meant to be used once. But they can hold hot food, oily food, and even soup for hours without breaking. If you’re asking about storage, they last over 2 years in dry conditions. I’ve shipped plates overseas that arrived in perfect condition even after long transit times.

8. Where can I buy these bamboo plates in bulk?

You can purchase directly from our factory — PANABAM, located in China. We’re a certified manufacturer with 10+ years of experience, supplying to the U.S., Australia, Germany, and more. You can contact me via info@panabam.com, visit www.panabam.com, or connect with me on Alibaba, LinkedIn, or at international trade shows.

9. Can I customize bamboo plates with my brand logo or packaging?

Yes, absolutely. We offer OEM & ODM services, including embossed logo, custom sizes, color-matched packaging, and environmental certifications. Many of our B2B clients request customized packaging for weddings, eco-retail, or corporate gifting. Just tell me your requirements, and we’ll provide a free mockup and quotation.

Ann

Hi, I’m Ann, and with over 5 years of experience in the foodservice industry, I’ve had the pleasure of working with restaurants and catering businesses to develop eco-friendly, tailored solutions that help you thrive in today’s green economy. I’m passionate about sustainability and committed to providing high-quality products that align with your values.

If you’re looking to make the switch to eco-friendly, sustainable tableware, I’m here to help! Reach out today, and let’s explore how we can support your business’s goals while contributing to a healthier planet.