As environmental regulations tighten, biodegradable tableware has become a vital tool for companies committed to sustainability. Among the many materials available, bamboo pulp and sugarcane pulp (bagasse) are the most common—but they differ significantly in sustainability, safety, performance, and usage scenarios.

Bamboo pulp and sugarcane pulp are popular materials for eco-friendly tableware, each with its own advantages. This article helps you choose between the two.

With so many options, which one stands out as the best for your business? Let’s dive into the key comparisons between bamboo and sugarcane pulp.

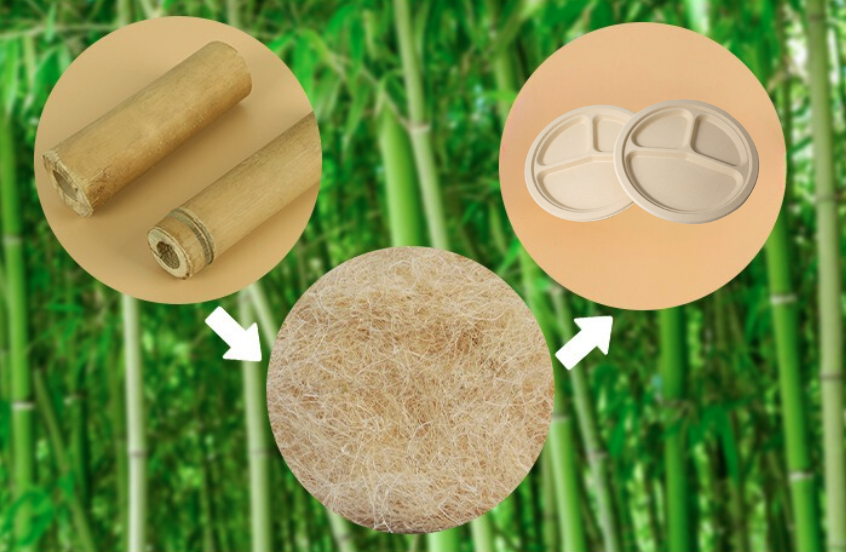

Raw Material Sustainability: Bamboo Pulp Leads the Way?

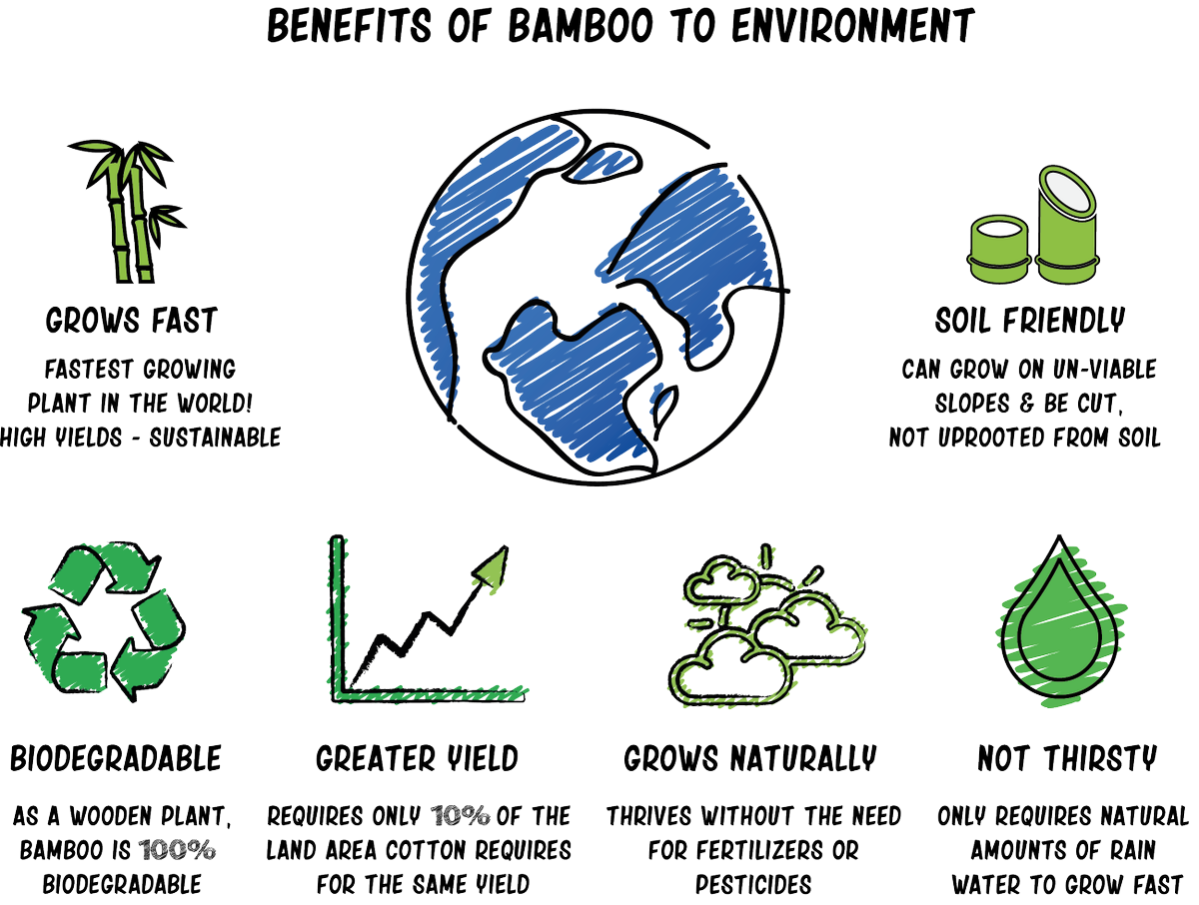

Bamboo pulp comes from natural bamboo, which can grow quickly, and it only takes about three years to mature. This means bamboo is available all year round, which provides a constant supply for manufacturing. It grows without the need for pesticides or fertilizers, making it a very sustainable resource. On the other hand, sugarcane pulp is derived from sugarcane, which is a by-product of sugar refining. However, sugarcane crops are seasonal, and they often require pesticides and fertilizers to grow.

Bamboo pulp offers traceable, pesticide-free sourcing and processing, making it a cleaner, greener choice for manufacturers.

Bamboo’s Cleaner, Greener Sourcing

Bamboo is one of the most sustainable materials on Earth. It can be cultivated without harming the environment or using harmful chemicals. Bamboo’s rapid growth cycle of 3 years also contributes to its sustainability, as it quickly regenerates and absorbs carbon dioxide, making it an important resource in combating climate change.

Sugarcane pulp, however, is a by-product of sugar production. While it is technically a renewable resource, it requires intensive farming methods and uses more chemicals. Some sugarcane farmers rely on pesticides and fertilizers, which can damage the ecosystem. In addition, sugarcane is only harvested once a year, making its availability seasonal, unlike bamboo which can be grown year-round.

| Comparison Criteria | Bamboo Pulp | Sugarcane Pulp (Bagasse) |

|---|---|---|

| Raw Material Source | Natural bamboo, year-round supply | By-product of sugar refining, seasonal |

| Cultivation Method | No pesticides, organic growth | Often uses pesticides/fertilizers |

| Processing | No bleaching, no additives | High-temperature cooking, uses bleach |

Eco-Friendliness & Degradability: Bamboo Is Truly Fully Biodegradable?

Bamboo pulp is fully biodegradable without needing additional chemical coatings, making it one of the most eco-friendly choices for tableware. It naturally breaks down in composting environments, leaving no harmful residues behind. In contrast, sugarcane pulp, while also biodegradable in its uncoated form, often requires coatings to enhance its resistance to water and oil. These coatings, especially fluorinated ones, may not break down fully, making sugarcane pulp less eco-friendly.

Bamboo pulp is fully biodegradable and requires no chemical coatings, whereas sugarcane pulp may include harmful coatings that reduce its environmental benefits.

Bamboo’s Environmental Edge

When it comes to sustainability, bamboo pulp holds a clear advantage over sugarcane pulp. Bamboo is a completely biodegradable material. There are no harmful additives or chemical coatings needed, ensuring that once the product is disposed of, it will break down and return to the soil without polluting it.

Sugarcane pulp, however, is often treated with coatings like PE, PLA, or fluorinated materials to make it resistant to moisture and grease. These coatings can hinder the material’s ability to biodegrade fully, meaning that sugarcane pulp products might not break down as cleanly as bamboo pulp. Additionally, these coatings can contaminate composting or recycling processes, making them harmful to the environment.

| Material | Degradability | Coating Requirement |

|---|---|---|

| Bamboo Pulp | 100% biodegradable | None required |

| Sugarcane Pulp | Depends on coating | Requires coating for oil/water resistance |

Performance: Bamboo Pulp Excels in Strength and Versatility?

Bamboo pulp tableware is known for its strength, heat resistance, and versatility. It can withstand temperatures up to 220°C, making it safe for use in microwaves and ovens for short durations. It is also freezer-safe down to -20°C, which makes it ideal for both hot and cold food applications. On the other hand, sugarcane pulp is less versatile. It can only handle temperatures up to 95°C and is not suitable for oven use. It is also prone to deformation under cold conditions.

Bamboo pulp is engineered to handle extreme temperatures, both hot and cold, making it ideal for diverse food service needs, unlike sugarcane pulp.

How Bamboo Outperforms Sugarcane in Practical Use

When it comes to performance, bamboo pulp stands out as the more reliable option. Its heat resistance is much higher than that of sugarcane pulp. Bamboo pulp products can be used in ovens, microwaves, and freezers, which makes them versatile for different types of food services. This means that bamboo pulp is a great option for both hot and cold meal packaging, as well as delivery services.

In contrast, sugarcane pulp can’t withstand high heat and will start to deform or even leach chemicals at temperatures above 95°C. This limitation makes it unsuitable for certain applications, such as catering to hot foods or using it in microwave- or oven-based meal delivery services.

| Attribute | Bamboo Pulp | Sugarcane Pulp |

|---|---|---|

| Heat Resistance | Up to 220°C (microwave/oven) | Up to 95°C |

| Cold Resistance | Freezer-safe (-20°C) | Easily deforms in cold |

| Water/Oil Resistance | Naturally resistant | Requires chemical coatings |

| Strength & Hardness | High strength | Softer, prone to deformation |

Shelf Life & Storage: Bamboo Is More Reliable for Long-Term Use

Bamboo pulp has an impressive shelf life of up to three years when stored in appropriate conditions. It is moisture-resistant, making it perfect for long-term storage and export. Sugarcane pulp, on the other hand, has a shorter shelf life. Uncoated sugarcane pulp products last about six months, while coated products can last up to two years. However, the coated versions are less environmentally friendly due to the added chemicals.

Bamboo pulp offers long-term reliability for storage and export, making it a practical choice for businesses that require consistent supply.

Bamboo’s Storage Advantage

Bamboo pulp’s storage stability is a significant advantage for businesses, especially those involved in large-scale exports. Due to its moisture resistance, bamboo pulp can be stored for up to three years without degrading. This makes it ideal for international shipping, where long transit times may otherwise damage products.

In contrast, sugarcane pulp is more susceptible to moisture, which can cause it to deteriorate quickly if not stored properly. Uncoated sugarcane pulp has a shelf life of only six months, while coated versions can last longer but are less eco-friendly. Bamboo’s superior storage properties make it a more practical option for businesses looking for long-term reliability.

| Material Type | Shelf Life | Storage Stability |

|---|---|---|

| Bamboo Pulp | Up to 3 years | Moisture-resistant |

| Sugarcane (Uncoated) | Around 6 months | Moisture-sensitive |

| Sugarcane (Coated) | Up to 2 years | Less eco-friendly |

Purity & Food Safety: Bamboo Pulp Is Naturally Clean

Bamboo pulp is naturally antimicrobial, meaning it doesn’t require additional sterilization. This makes it a cleaner option for food safety. It also has low levels of impurities, maintaining high visual and tactile quality. In contrast, sugarcane pulp often requires additional disinfection and can have higher levels of impurities, which may affect its appearance and use.

Bamboo pulp’s natural purity and antimicrobial properties make it a safer and cleaner choice for food service applications compared to sugarcane pulp.

Bamboo’s Food Safety Superiority

Food safety is crucial when choosing a material for tableware. Bamboo pulp has the natural advantage here. It is antimicrobial, meaning it resists bacteria without requiring additional chemicals. This makes it safer for use in food applications, where hygiene is critical. It is also free from harmful chemicals, ensuring that there is no risk of contamination from pesticides, bleach, or other additives.

Sugarcane pulp, while biodegradable, often contains residues from pesticides or bleach used in its cultivation and processing. This may lead to potential allergen risks or contamination, which is a concern for sensitive consumers or businesses aiming for strict food safety standards.

| Comparison Criteria | Bamboo Pulp | Sugarcane Pulp |

|---|---|---|

| Microbial Control | Naturally antimicrobial | Requires disinfection |

| Impurity Level | Low impurities | Higher impurities |

| Allergen Risk | Low allergen potential | Possible chemical residues |

Conclusion

Bamboo pulp offers a cleaner, more sustainable, and practical solution for biodegradable tableware. Its superior performance, biodegradability, and food safety make it the best choice for eco-conscious businesses looking to switch to sustainable options.

Ann

Hi, I’m Ann, and with over 5 years of experience in the foodservice industry, I’ve had the pleasure of working with restaurants and catering businesses to develop eco-friendly, tailored solutions that help you thrive in today’s green economy. I’m passionate about sustainability and committed to providing high-quality products that align with your values.

If you’re looking to make the switch to eco-friendly, sustainable tableware, I’m here to help! Reach out today, and let’s explore how we can support your business’s goals while contributing to a healthier planet.