Plastic plates look cheap and easy, but they can create waste, risk, and complaints. I help buyers choose plates that work and still meet new rules.

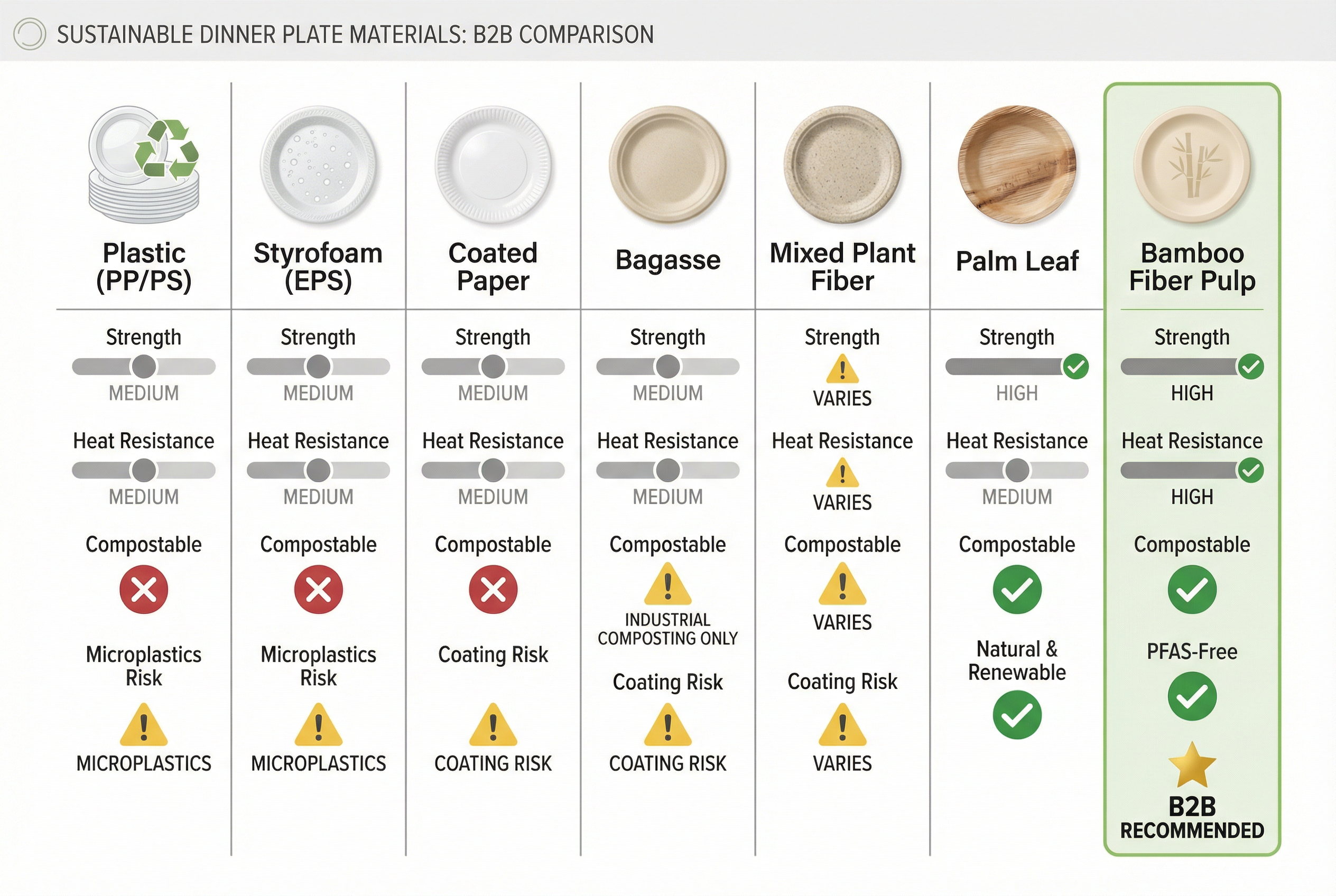

The best disposable dinner plate material depends on strength, heat, coatings, and end-of-life. In most B2B food service cases, uncoated, PFAS-free bamboo fiber pulp offers the best balance of performance, safety, and compostability.

If you sell meals, you cannot guess here. So I will compare materials in a direct way, and I will also answer the buyer questions I hear every week.

Why does material choice matter more than ever?

Plastic bans and brand pressure can make one plate choice feel like a big risk. So I look at material first, because material controls cost, complaints, and compliance.

Material matters because it drives real performance and real end-of-life. It also affects chemical exposure, local plastic rules, and how customers judge your brand at the table.

If you only compare prices per plate, you will miss the hidden costs. So I will start with what changed, and then I will show what “best” really means in 2026 buying.

The market changed, so “disposable” changed too

Many buyers grew up with plastic, foam, and coated paper. I did too. But now many cities and large buyers ask for compostable options. Also, customers see the plate as part of the meal. So the plate can help you, or it can hurt you.

I remember a catering client who used cheap coated paper. The food was hot and oily. The plate softened. Then staff doubled plates. So the “cheap” plate became expensive. Also, trash volume grew. So the client paid more for hauling. And the photos of soggy plates did not help their brand.

“Best” depends on your use case, not on slogans

Some brands say “eco.” Some say “compostable.” But the truth depends on:

- what coatings exist,

- what temperature you serve,

- how greasy the food is,

- and where the waste goes.

So I do not accept claims without looking at structure, coatings, and end-of-life.

What I will answer in this guide

I will answer these buyer questions in plain language:

- What are the most environmentally friendly disposable plates?

- What are the strongest disposable plates?

- What material is 100% biodegradable?

- What is the best alternative to plastic plates?

- Which paper plate is the healthiest?

Quick decision map

| Your main need | What matters most | Materials that often win |

|---|---|---|

| Heavy, oily meals | rigidity + grease resistance | bamboo fiber pulp, some premium plant fiber |

| Lowest cost today | unit price | coated paper, some bagasse, but watch double-plating |

| “Natural look” for events | visual + story | palm leaf, bamboo fiber |

| Simple compost messaging | verified compostability + no PFAS | PFAS-free bamboo fiber pulp, PFAS-free bagasse |

| High-volume programs | stable supply + consistent specs | bamboo fiber pulp, bagasse at scale |

I will now define the terms, because many mistakes start there.

What is the real difference between disposable and compostable plates?

Many sellers use these words like they mean the same thing. But they do not. So I define them before I compare materials.

Disposable means single-use. Compostable means it can break down under compost conditions into safe organic material. All compostable plates are disposable, but not all disposable plates are compostable.

If you buy for a business, this difference can decide if you pass a customer audit. So I will explain industrial vs home composting in a practical way.

Definitions that buyers can use in a contract

Disposable plates: Plates designed for one use. They usually go to trash. Many are plastic, foam, or coated paper. So they often end in landfill. Also, some can fragment and create microplastics.

Compostable plates: Plates designed to break down into compost under the right conditions. They should not leave toxic residues. But the key is “right conditions.”

Industrial composting vs home composting

This part matters because “compostable” can still fail in real life.

Industrial composting

Industrial sites control:

- heat,

- moisture,

- oxygen,

- and time.

So many compostables break down faster there. But many cities do not have industrial compost for foodware. Also, some sites reject foodware if it looks like plastic.

Home composting

Home compost is cooler and less controlled. So only some materials break down well at home. Natural fibers often do better than some bioplastics. But thickness and coatings still matter.

The hard truth about end-of-life

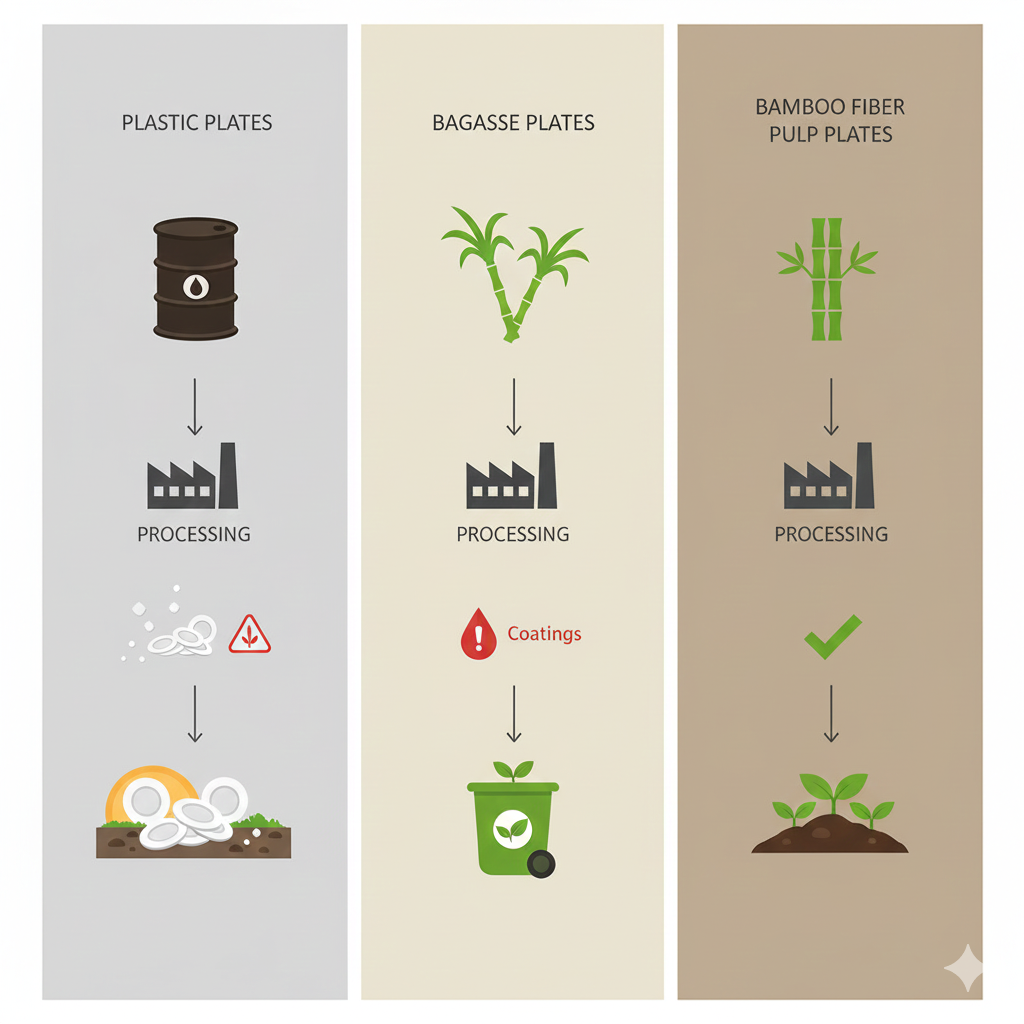

Even a good compostable plate can end in landfill. So I ask: if it lands in trash, does it still avoid microplastics and toxic residues? This is why coatings matter so much.

Practical label language I look for

| Claim on packaging | What I check next | Why it matters |

|---|---|---|

| “Compostable” | home vs industrial details | many items need industrial systems |

| “Plant-based” | coatings, binders, additives | plant-based can still include plastic lining |

| “PFAS-free” | test reports or supplier statement | grease resistance often uses PFAS |

| “Biodegradable” | what conditions, what timeline | vague claims can mislead |

Now that the terms are clear, I will list the main materials you will see in the market.

What material are disposable plates made of?

Buyers ask this because material controls performance and compliance. So I will name the major categories and how they are made.

Disposable plates are commonly made from plastic, foam, coated paper, or molded plant fibers like bagasse, bamboo fiber, mixed plant fiber, and palm leaf. Each method changes strength and compostability.

If you understand the manufacturing path, you can predict failure points. So I will keep it simple and practical.

Plastic (polystyrene, polypropylene)

Plastic plates are formed by heat and pressure, then cut and shaped. They can be rigid. But they are fossil-based. Also, they are not compostable. And recycling is limited in real use because plates are food-soiled.

Styrofoam (expanded polystyrene)

Foam plates are expanded with gas. They feel light. But they break into pieces. Also, many regulations target foam. And they do not compost.

Coated paper (pulp with coatings)

Paper plates start as tree pulp. Then makers add coatings for grease and water resistance. Some use plastic coatings. Some used PFAS for grease resistance. So the coating can block composting even if the base is paper.

Sugarcane bagasse

Bagasse is the fiber left after making sugar juice. Manufacturers mold it like pulp. So it can become plates and clamshells. It can be compostable. But grease performance can depend on coatings and process control.

Generic “plant fiber” blends

These plates can mix fibers like bamboo, wheat straw, and other agricultural fibers. Performance varies a lot. Some blends are strong. Others are soft. So the category name alone is not enough.

Palm leaf

Palm leaf plates are pressed from fallen leaves. So they can be very natural. But thickness can vary. Also, supply scale can be limited.

Bamboo and bamboo fiber pulp

Bamboo can be used as pressed bamboo, or as molded bamboo fiber pulp. Bamboo grows fast. Also, it can provide high tensile strength in fiber form. So it can hold hot and oily foods well when engineered correctly.

Next, I will compare all materials in one structured table, because buyers need one view.

Which material makes the best disposable dinner plate in real B2B use?

Many articles pick one “best” without showing trade-offs. I do the opposite. I compare performance, sustainability, and safety, because you need all three.

In most food service settings, PFAS-free, uncoated bamboo fiber pulp plates deliver the best overall balance of strength, heat resistance, and compostable end-of-life, while also avoiding microplastics and many coating risks.

Now I will show the comparison table first, and then I will explain each material with pros and cons.

Comparison table: performance, sustainability, and safety

| Material | Raw source | Coatings needed? | Strength with heavy/oily food | Heat range (typical use) | Compostability | Microplastics/toxic residue risk | Eco score (practical) | B2B suitability |

|---|---|---|---|---|---|---|---|---|

| Plastic (PP/PS) | fossil | none, but plastic itself | medium to high | medium | not compostable | high microplastics risk | low | declining in many markets |

| Styrofoam (EPS) | fossil | none | medium, but cracks | low to medium | not compostable | high fragmentation risk | very low | high regulatory risk |

| Coated paper | trees | often yes (plastic/PFAS/wax) | low to medium | low to medium | often blocked by coating | medium to high | low to medium | common but can fail |

| Bagasse | ag by-product | sometimes | medium | medium | often industrial; some home | low to medium (depends on coating) | medium to high | good if coating-free |

| Mixed plant fiber | plant blend | often | varies | varies | varies | varies | medium | supplier-dependent |

| Palm leaf | fallen leaves | no | high, but inconsistent | medium | home/industrial | low | high | small to medium scale |

| Bamboo fiber pulp | renewable bamboo | can be none | high | high | home/industrial (if uncoated) | low | very high | excellent for programs |

Plastic and Styrofoam plates

Why they are not environmentally friendly

Plastic and foam are fossil-based. They do not compost. They can last for a very long time. Also, they can break into smaller parts. Those parts can spread as microplastics. So even if you collect waste, some leakage happens.

“What is the best plastic material for plates?”

If you force me to pick “best plastic,” I would say some plastics perform better than others for heat and rigidity. But that still misses the core point. They still depend on fossil feedstock. They still do not compost. Also, many bans and corporate rules target plastic foodware. So “best plastic” can still be a future problem.

Coated paper plates

Paper plates look simple, but the coating makes the real difference. Many plates use coatings for grease. Some coatings block composting. Also, some coatings raise health concerns. Paper also links to forestry impacts, plus water and chemicals used in pulp processing.

Sugarcane bagasse plates

Bagasse uses a waste stream from sugar. So the raw material story can be strong. Also, molded bagasse can work for many foods. But some bagasse plates soften with very hot and oily meals. And many brands used grease barriers that buyers now question. So I always ask about PFAS and barrier choices.

Plant fiber and mixed fiber plates

This is a wide category. Some are strong and clean. Some are weak and need coatings. So the label “plant fiber” alone does not tell you enough. I ask for:

- density specs,

- thickness,

- oil resistance method,

- and heat tolerance data.

Palm leaf plates

Palm leaf can be very natural. It can also be compostable with no coating. But thickness can vary. Also, the surface can be uneven. Some buyers love the look for weddings. But large chains can struggle with consistency, audits, and supply scale.

Bamboo and bamboo fiber pulp plates

Bamboo grows fast, and it can regenerate without replanting in many systems. Also, bamboo fiber can create strong molded structures. When bamboo fiber pulp plates are made without plastic or PFAS coatings, they can stay rigid with hot and oily foods. They also avoid microplastics at end-of-life. This is why many B2B programs pick bamboo fiber pulp when performance matters and rules are strict.

A quick “best” decision table

| Use case | Best-fit materials | Why |

|---|---|---|

| Hot + oily + heavy meals | bamboo fiber pulp | rigidity + heat + grease resistance |

| Cold meals, light snacks | bagasse, mixed fiber | often good enough, often cheaper |

| Premium natural look | palm leaf, bamboo | story and appearance |

| Lowest compliance risk | PFAS-free bamboo fiber pulp | coating-free pathway, clear messaging |

Now I will answer the big PPA question about “most environmentally friendly.”

What are the most environmentally friendly disposable plates?

Many buyers want one simple answer. I give one, but I also explain the criteria, because “eco” can be marketing noise.

The most environmentally friendly disposable plates use renewable fibers, avoid PFAS and plastic coatings, and can compost into safe organic matter. PFAS-free bamboo fiber pulp often ranks highest, with well-designed bagasse and palm leaf close behind.

If you want fewer surprises, you need a checklist that is easy to audit. So I will show my criteria and a simple ranking logic.

Criteria I use for eco-friendliness

1) Renewable feedstock

I prefer:

- bamboo,

- bagasse,

- palm leaves, because they renew quickly or use by-products.

2) No fossil-based plastic and no foam

This removes:

- PP, PS, EPS, and also removes “paper + plastic lining” designs.

3) No PFAS or other harmful grease coatings

Grease barriers matter, but chemical choices matter too. So I prefer natural barrier methods or verified PFAS-free systems.

4) Verified compostability, plus “safe if landfilled”

I like compostability, but I also ask what happens if it goes to landfill. Natural fibers without plastic linings do not create microplastics like plastics do.

A practical eco ranking for food service

| Rank (typical) | Material | Why it ranks here | What can reduce the score |

|---|---|---|---|

| 1 | PFAS-free bamboo fiber pulp | renewable + strong + coating-free possible | poor process control, unclear additives |

| 2 | Palm leaf | minimal processing + no coating | inconsistent thickness, limited scale |

| 3 | PFAS-free bagasse | uses by-product + compostable | grease barriers that include PFAS |

| 4 | Mixed plant fiber | can be tree-free and compostable | unknown blend, coatings, weak specs |

| 5 | Coated paper | familiar and cheap | plastic/PFAS coatings, forestry impact |

| 6 | Plastic/foam | performance is not the problem | end-of-life and regulation risk |

The honest trade-off

Bagasse can be great because it uses waste. But if it uses PFAS for grease resistance, its health and compost story weakens. Palm leaf can be clean, but supply scale can be hard. Bamboo fiber pulp can scale, and it can be made PFAS-free, but it can cost more. So the best eco choice is the one that you can buy consistently and also defend in audits.

Next, I will answer “100% biodegradable,” because buyers ask it often and it has traps.

What material is 100% biodegradable?

This question sounds simple, but many sellers twist the words. So I separate biodegradability from compostability and from “breaks into pieces.”

Natural fibers like bamboo, bagasse, and palm leaf can be fully biodegradable when they have no plastic or PFAS coatings. Plastics and foam do not biodegrade; they mostly fragment. Many bioplastics need industrial composting to break down well.

If you want to protect your brand claims, you need to talk about conditions. So I will do that in a direct way.

Biodegradable is not the same as “disappears”

Some items just break into smaller pieces. That is not real biodegradation. Real biodegradation means microbes turn the material into natural components like water, CO₂, and biomass, with no toxic leftovers.

Plastics and Styrofoam

Plastics and foam are not “100% biodegradable” in normal nature conditions. They can take a very long time. Also, they can break into microplastics. So the problem can spread, not shrink.

PLA and many “bioplastics”

Some bioplastics can compost, but often only in industrial composting. So in a backyard compost, they can sit for a long time. Also, in landfill, they may not break down as promised.

Natural fiber plates

Natural fibers like bamboo fiber, bagasse fiber, and palm leaf can biodegrade well. But only if coatings do not block water and microbes. So I always ask:

- Is there a plastic lining?

- Is there PFAS for grease?

- Is there heavy ink or lamination?

Why bamboo fiber pulp can be a clean answer

If a bamboo fiber plate is made without plastic or PFAS coatings, it can break down into organic matter. Also, it can avoid microplastics. That is why I like it for buyers who want a clear, simple sustainability story.

A buyer-ready “100% biodegradable” checklist

| Check item | What I want to hear | What makes me pause |

|---|---|---|

| Coatings | “No plastic, no PFAS” | “Proprietary barrier” with no proof |

| Additives | “Plant-based binder” | unknown additives, no disclosure |

| Disposal | home + industrial compost options | “industrial only” with no local access |

| Proof | compostability test or certification | only marketing claims |

Now I will answer the strength question, because strength drives customer complaints and hidden costs.

What are the strongest disposable plates?

Strength is not only “hard.” Strength also means the plate stays rigid with hot, wet, oily food. So I compare how plates fail in real service.

The strongest disposable plates are usually palm leaf and high-quality bamboo fiber pulp. Bamboo fiber pulp often wins on consistency, rigidity, and performance with heavy, oily, or saucy foods in high-volume B2B use.

If a plate bends, staff will double it. Then cost rises fast. So strength is a cost issue, not only a quality issue.

How plates fail in real life

I look at four failure modes: 1) bending under load, 2) softening with heat, 3) soaking with oil or water, 4) cracking at edges.

Coated paper: strong enough, but often needs doubling

Many coated paper plates handle light meals. But with hot and oily foods, they can soften. So staff may add a second plate. So waste and cost go up. Also, coatings can complicate composting.

Bagasse: good structure, but can soften with hot oil

Bagasse plates can be solid for many uses. But with hot oil and long holding time, some brands soften. It depends on density, thickness, and barrier approach.

Palm leaf: very strong, but not always consistent

Palm leaf plates can be surprisingly strong. But thickness can vary. So one batch can feel perfect, and the next can feel uneven. This is fine for boutique events, but it can be hard for chains.

Bamboo fiber pulp: strong and consistent when engineered well

Bamboo fiber has high tensile strength. In molded pulp form, it can create rigid plates that resist bending. Also, modern bamboo fiber pulp can handle hot, oily, saucy dishes without warping when the process is controlled. So this is why restaurants, catering, airlines, and events often prefer it for “no-fail” service.

Strength comparison table for buyers

| Material | Load rigidity | Grease resistance | Heat stability | Batch consistency |

|---|---|---|---|---|

| Coated paper | low to medium | medium | low to medium | high |

| Bagasse | medium | medium | medium | medium |

| Palm leaf | high | high | medium | low to medium |

| Bamboo fiber pulp | high | high | high | high |

Now I will talk about “healthiest paper plates,” because the word “paper” can hide chemical choices.

Which paper plate is the healthiest to use?

People often assume paper is always safe. But coatings, inks, and bleaching choices matter. So I focus on what touches food.

The healthiest paper plates are those with no PFAS, no plastic lining, and verified food-contact compliance. In many cases, PFAS-free bamboo fiber plates and clean plant-fiber plates can be healthier than traditional coated paper plates.

If you sell food, health questions can become reputation questions. So I treat this like risk control.

What health risks buyers worry about

PFAS for grease resistance

Some paper and bagasse plates used PFAS to stop oil. PFAS can persist in the environment. So buyers now ask for PFAS-free options.

Plastic linings and unknown barriers

Some “paper” plates include plastic layers for water resistance. That can affect end-of-life. Also, it can raise questions about additives.

Inks, dyes, and heavy bleaching

Printed plates can transfer ink if not controlled. Also, heavy bleaching can be part of pulp processing. So I prefer clean, controlled processes.

Healthiest criteria I use

| Criteria | Why I use it | What I ask suppliers |

|---|---|---|

| PFAS-free | reduces chemical concern | “Show PFAS-free statement or test” |

| No plastic lining | avoids plastic contact and waste issues | “Is there any PE/PLA film?” |

| Food-contact compliance | proves basic safety | “FDA, LFGB, or equivalent?” |

| Low odor and no taste | protects food quality | “Any odor tests or feedback?” |

Why bamboo fiber plates can score well

Bamboo fiber plates can be made without PFAS, bleach, plastic, wax, or PLA lining. Also, bamboo fiber can give natural grease resistance when process and binder choices are right. So for many buyers, this becomes a safer and simpler story than “paper + coating.”

A quick buyer script I use

When a buyer asks me, “Which paper plate is the healthiest?” I answer like this:

- I ask what coatings exist.

- Then I ask if it is PFAS-free.

- Then I ask for food-contact compliance documents.

- Then I check if the plate stays rigid without extra lining.

Next, I will answer the plastic-alternative question, because it is often tied to bans and contracts.

What is the best alternative to plastic plates?

Many buyers still compare everything to plastic, because plastic sets the old baseline for strength and price. But “best alternative” now means performance plus future safety.

The best alternative to plastic plates is usually molded plant fiber that is PFAS-free and coating-free, with bamboo fiber pulp often leading for strength, heat resistance, and compostable end-of-life.

If you want a smooth transition away from plastic, you need a material that feels familiar in use. So I compare the leading alternatives.

Comparing the main plastic alternatives

Coated paper

It can be cheap and familiar. But it can fail with heavy meals. Also, coatings can block composting and raise health questions.

Bagasse

It can be a solid upgrade from coated paper. It uses an agricultural by-product. But quality varies, and some products use grease barriers that you may not want.

PLA and bioplastic blends

They look modern, but they often need industrial composting. Also, they can confuse sorting and contaminate recycling or compost streams.

Palm leaf

It looks premium and natural. But supply and consistency can be harder for large programs.

Bamboo fiber pulp

It can match plastic-like rigidity. It can handle heat and oil. And it can be fully plant-based and compostable when made without coatings. Also, it can scale for B2B.

Why bamboo fiber stands out for B2B

| Factor | Why it matters in business | Bamboo fiber pulp impact |

|---|---|---|

| Future compliance | bans and customer rules change fast | lower risk than plastic |

| Customer experience | plates show up in reviews and photos | stable, premium look |

| Hidden costs | double-plating and waste hauling | fewer failures, less doubling |

| Supply stability | programs need consistent SKUs | scalable when factory-backed |

Next, I will revisit the environment question and rank options again, but with lifecycle trade-offs in mind.

Which disposable plates are best for the environment?

This question looks like the earlier eco question, but here buyers want a ranking they can defend. So I talk about lifecycle trade-offs, not only “plant-based” labels.

Disposable plates that are best for the environment are typically uncoated natural fiber plates that are PFAS-free and compostable, with bamboo fiber pulp often offering the best balance of low-impact feedstock, strong performance, and scalable supply.

If you want to avoid greenwashing, you need to admit trade-offs. So I will do that clearly.

Lifecycle thinking in simple steps

I use three steps: 1) where the raw material comes from, 2) what processing and coatings are used, 3) what happens after use.

Trade-offs you should not ignore

Bagasse: waste valorization vs chemical barriers

Bagasse uses a by-product, which is good. But grease resistance can push some makers toward coatings. So the end-of-life story can weaken if coatings are problematic.

Palm leaf: natural origin vs limited scale

Palm leaf can be very clean. But if you need millions of plates with strict specs, scale and consistency can limit it.

Bamboo fiber pulp: strong balance vs higher unit cost

Bamboo can renew fast. It can also create strong plates without plastic or PFAS. But cost can be higher than paper or low-end bagasse. So buyers need to compare total cost, not only unit price.

Environment ranking with “marketing risk” included

| Material family | Environmental strength | Main risk | My practical note |

|---|---|---|---|

| PFAS-free bamboo fiber pulp | very high | cost focus only | compare total cost and risk |

| Palm leaf | high | supply and consistency | best for premium events |

| PFAS-free bagasse | high | coating choices vary | ask for PFAS-free proof |

| Mixed plant fiber | medium to high | unknown blends | require specs and tests |

| Coated paper | low to medium | coating blocks compost | can be “paper” only in name |

| Plastic/foam | low | microplastics + bans | future risk is high |

Now I will answer the “best brand” question in a B2B way, because buyers mean something specific by “brand.”

What’s the best brand of disposable plates for B2B buyers?

This question is not really about a logo. It is about risk, supply, and proof. So I answer it like a buyer, not like a consumer reviewer.

For B2B, the best brand is the one that can prove material safety, deliver consistent quality at scale, support customization, and meet target market rules. A factory-backed producer with stable lines often beats a trading-only label.

If you buy wholesale, you need a partner, not only a product. So I explain what I look for, and then I show where PANABAM fits.

What “best brand” means in B2B

Proven material and certifications

I need evidence for:

- food-contact compliance,

- compostability pathways,

- and PFAS-free claims if grease resistance is promised.

Large-scale, stable supply chain

A “best brand” must ship reliably. So I check:

- number of production lines,

- output capacity,

- and quality control processes.

Consistent quality and customization

B2B buyers want the same plate every time. Also, they may want:

- logo emboss,

- packaging,

- and size or shape changes.

Compliance across markets

If you export to the US, EU, UK, Australia, and Japan, you face different expectations. So I value suppliers with multi-market experience.

Where PANABAM fits in this definition

I work with PANABAM’s positioning as a factory-level producer of bamboo fiber pulp tableware and food service packaging. The factory has multiple production lines and long operating history. Also, the focus is on automated, integrated production for consistency at scale. This matters because many “eco” products fail on repeatability, not on marketing.

A simple brand evaluation table

| Brand check | What I want | How I verify |

|---|---|---|

| Material transparency | clear fiber + binder info | spec sheet and samples |

| Coating disclosure | PFAS-free, plastic-free | written statement, tests |

| Consistency | same weight and rigidity | batch sampling |

| Supply capacity | stable lead times | factory plan, past shipments |

| Customization | molds, packaging, logo | tooling plan and MOQ |

| Support | fast responses, clear docs | pre-order communication |

Next, I will give a buyer checklist you can use to choose plates fast, because time is always tight.

How do I choose the best disposable plate for my business?

Many buyers want a short list they can hand to a team. So I use a checklist that prevents the most common failures: soft plates, coating surprises, and compliance gaps.

Choose a disposable plate by checking material and coatings first, then certifications, then strength and heat specs, and finally end-of-life options in your target markets. This approach reduces complaints and future compliance risk.

If you follow this order, you avoid buying the wrong “eco” plate that looks good only on a product page.

Step 1: Material and coatings

I start here because coatings can cancel compostability and create health questions.

- I ask if it is PFAS-free.

- I ask if it is plastic-free.

- I ask if the grease barrier is disclosed.

Step 2: Certifications and documents

I do not rely on slogans. I ask for:

- food contact compliance,

- compostability proof if claimed,

- and test reports if available.

Step 3: Strength and temperature resistance

I match the plate to the food.

- For hot meals, I need high heat stability.

- For oily meals, I need real grease resistance.

- For heavy meals, I need rigidity.

Step 4: Composting options in target markets

If your city has industrial compost, some options open up. If not, home-compost-friendly natural fibers can be safer. But you still need honest messaging.

Step 5: MOQ, pricing, and customization

Price matters, but hidden costs matter too.

- I compare unit cost and failure cost.

- I check if doubling happens.

- I check if packaging damage happens.

A practical buyer checklist table

| Checklist item | Pass standard | Why it saves money |

|---|---|---|

| Coatings | PFAS-free, plastic-free | avoids compliance and health risks |

| Strength | no bending with sample load | reduces double-plating |

| Heat | stable with hot food | prevents warping and leaks |

| Grease | holds oily food 30–60 minutes | protects customer experience |

| Documents | food-contact compliance | reduces legal and audit issues |

| Supply | stable lead time | prevents outages |

Why bamboo fiber pulp often fits the checklist

Bamboo fiber pulp plates can meet strength and heat needs, and they can also be compostable and biodegradable without microplastics when they avoid plastic and PFAS coatings. Also, factory-scale production supports stable supply for restaurants, caterers, retailers, and institutions.

Now I will close with a direct synthesis, because buyers need one final answer they can repeat inside their company.

Conclusion

Bamboo fiber pulp plates balance strength, heat, PFAS-free safety, and compostable end-of-life, so they often beat plastic, paper, and bagasse.

Shmily Lee

Hi there! I’m Shmily, a proud mom to an amazing boy and the manager of PANABAM. We’ve been producing eco-friendly bamboo tableware that’s both sustainable and high-quality. I’m passionate about helping businesses embrace greener solutions. Let’s connect and create a more sustainable future together!