![]()

Plastic straws create risk for my buyers. They face bans, complaints, and supply shocks. So they need a safer replacement.

The best plastic straw alternatives in 2026 include bamboo fiber, paper, reusable bamboo, stainless steel, glass, silicone, sugarcane, and PLA-like options, but performance and compliance vary by market.

Why are plastic straw bans accelerating in 2026?

Plastic straws used to feel “small.” But now they cause big headaches for cafés, brands, and importers. So buyers must switch fast.

Plastic straw bans are expanding, so foodservice buyers need compliant alternatives that avoid fines, customs delays, and customer complaints.

What is changing in the real market?

I talk with buyers from the US, Canada, and Europe every week. And I hear the same pattern. Rules get stricter. But also customers get louder. So the straw becomes a visible “proof” of sustainability. If the straw fails, the drink experience fails. And if the material is not accepted in a local policy, the whole shipment becomes a risk.

I also see a new buyer behavior. Many buyers do not only ask “Is it biodegradable?” They ask “Will it pass our local compliance checks?” and “Will it last in iced coffee?” and “Will it trigger bad reviews?” So a straw is now both a compliance item and a customer-experience item.

Why “plant-based” is not the same as “accepted”

This is where many teams get confused. A product can be “plant-based,” but still be treated as plastic in some markets. And a product can be “biodegradable” in lab language, but still fail in real disposal systems. So I always tell buyers: first map your sales countries, then map the materials accepted there, and then test performance.

What signals do I use to judge urgency?

I use three signals. First, buyers tell me their local inspectors are more active. Second, retailers ask for clear certificates and clean claims. Third, brands want simple messaging. They want “plastic-free” and “compostable,” not a long explanation.

| Pressure Source | What I see buyers experience | What it forces them to do |

|---|---|---|

| Regulation and enforcement | More bans, more checks, more rejected listings | Choose safer materials and clearer labels |

| Consumer expectation | “Paper straw hate” reviews and refund requests | Upgrade performance, not just marketing |

| Supply chain risk | Delays, reworks, surprise costs | Standardize specs and pick reliable factories |

Because of all this, I treat straw replacement as a strategic change. And then I plan content around the real decision process buyers follow.

What are the best plastic straw alternatives for B2B buyers?

Many teams search for “alternatives,” then they only get list posts. But lists do not help buyers choose. So I use a B2B comparison.

The best alternatives depend on drink type, time-in-cup, mouthfeel expectations, cleaning capacity, and local rules.

The 8 major alternatives I see in foodservice

When I look at real procurement, I see eight categories show up again and again:

1) Paper

2) PLA and similar bioplastics

3) Bamboo fiber (molded pulp fiber straws)

4) Reusable bamboo

5) Sugarcane (bagasse)

6) Stainless steel

7) Glass

8) Silicone

A complete B2B comparison table

I do not like vague claims. So I keep a simple matrix that buyers understand fast. I adjust it based on drink type and country. But this table is a strong starting point.

| Material | Degrades | Heat Resistance | Oil/Water Proof | Mouthfeel | Cost (relative) | B2B Rating | Biggest Issue |

|---|---|---|---|---|---|---|---|

| Plastic | ~400 years | High | ★★★★★ | ★★★★★ | ★★★★★ | ❌ Illegal in many places | Microplastics and bans |

| Paper | ~90 days (varies) | Medium | ★★☆☆☆ | ★☆☆☆☆ | ★★★★☆ | ★★☆☆☆ | Soggy and complaints |

| PLA | Industrial-only (often) | Low–Medium | ★★★☆☆ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | Not accepted in some markets |

| Stainless steel | Permanent | ★★★★★ | ★★★★★ | ★★☆☆☆ | ★☆☆☆☆ | ★★☆☆☆ | Cleaning and loss |

| Glass | Permanent | ★★★★★ | ★★★★★ | ★★★☆☆ | ★★☆☆☆ | ★☆☆☆☆ | Breakage risk |

| Silicone | Permanent | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ | Not biodegradable |

| Sugarcane (bagasse) | ~90 days (varies) | High | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | Deforms and coatings |

| Reusable bamboo | ~60 days (end-of-life varies) | High | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★★★☆ | Needs washing system |

| Bamboo fiber | ~30 days (good conditions) | Very high | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★★ | Needs the right supplier |

My “shortlist rule” for buyers

I use a simple rule. If a buyer sells drinks at scale, and they want plastic-like mouthfeel, and they want simple “plastic-free” messaging, then bamboo fiber becomes the front runner. But if they need very low cost for very short use, paper can still be acceptable. And if they sell premium experiences and they can wash, reusable bamboo can work well.

So the “best alternative” is not one material. It is a match between drink reality and business reality.

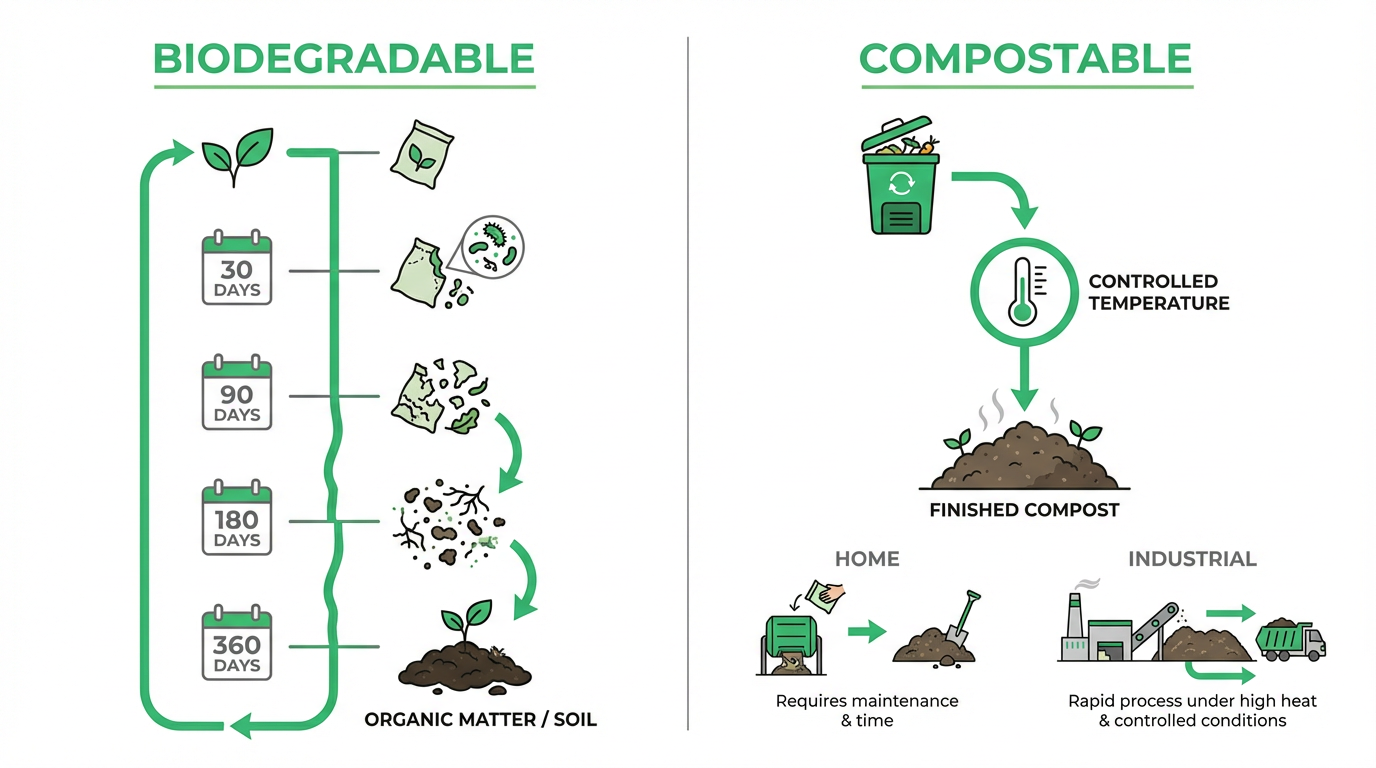

What is the difference between “biodegradable” and “compostable”?

Many brands lose trust here. They say “biodegradable,” but customers and regulators ask “under what conditions?” So the claim must be precise.

“Biodegradable” describes breakdown over time, while “compostable” implies a material can turn into compost under defined conditions without toxic residue.

Why this matters

I must answer what people actually ask. People ask “Is it really compostable?” and “Is it safe?” and “Is it greenwashing?” So I need clear definitions. But I also need to connect the definitions to daily use.

Practical truth: claims must meet disposal reality

Paper can break down, but it often fails in the cup. PLA can be marketed as compostable, but it often needs industrial composting conditions. And in some European countries, PLA is not accepted as “biodegradable” for certain single-use categories. This is exactly why I do not let buyers choose based on marketing terms alone.

I also see another issue. Some products use coatings to improve water resistance. But coatings can reduce real compostability. So I always ask: “What is the binder?” and “What is the coating?” and “Is it plastic-free?” This is not only technical. It is also a branding and compliance issue.

A simple buyer checklist

| Claim on product | What I ask next | Why I ask it |

|---|---|---|

| “Biodegradable” | In soil? In water? In compost? Timeframe? | Buyers need predictable end-of-life story |

| “Compostable” | Home or industrial? Which standard? | Many markets require proof, not slogans |

| “Plant-based” | Does it still contain plastic polymers? | Some “plant-based” items are still treated as plastic |

| “PFAS-free / coating-free” | How is oil resistance achieved? | Performance must not hide non-compostable chemistry |

What I tell buyers in one sentence

I tell buyers: “If you cannot explain the disposal path in one simple sentence, you will lose trust and you may also fail compliance.”

This is why I prefer bamboo fiber systems that are designed to be plastic-free and coating-free, while still staying strong in real drinks.

How does bamboo fiber perform in real café testing compared with paper and PLA?

Many content pieces stop at theory. But my buyers test. They put a straw into a hot latte and then they wait. So I do the same.

In café-style tests, bamboo fiber straws tend to last longer than paper and stay more stable than many PLA options in heat and time-in-cup conditions.

Why I trust testing more than claims

I learned this lesson early. A supplier can show a brochure. But a straw must survive: heat, ice, sugar, fat, and time. And it must feel good in the mouth. Also, it must not add taste. If it fails, customers complain. Then cafés lose repeat orders. So I always anchor the decision in tests.

Test setup I use with buyers

I keep it simple and repeatable. I pick two drinks that stress materials:

- Hot latte with cream (high heat + fat)

- Iced milk tea with pearls (time + friction + larger diameter demand)

Then I compare: paper vs PLA vs bamboo fiber.

Test 1: Hot latte + cream (about 85°C, 30 minutes)

- ✅ Bamboo fiber: stayed firm, no leakage, no collapse

- ❌ Paper: softened fast, then collapsed around 10–15 minutes

- ❌ PLA: softened or deformed in heat in some samples, and it created compliance questions for some markets

Test 2: Iced milk tea + pearls (45 minutes)

- ✅ Bamboo fiber: “plastic-like” mouthfeel, no aftertaste, pearls moved smoothly

- ❌ Paper: wet-paper taste, pearls stuck, straw got soft

- ✅/⚠️ PLA: often worked, but some buyers worried about local acceptance and end-of-life claims

Real buyer language matters

One Canadian coffee brand told me this, and I keep it as a real example of buyer intent:

“Cannot. PLA and other plastic straws are banned in Canada so we’re looking at more eco-friendly options… We were comparing manufacturers. From the quality testing, you guys had the best product. Their shipping option was also very expensive.”

This message tells me three things. First, compliance is not optional. Second, testing decides the winner. Third, logistics cost can break a deal. So when I write the blog, I must address all three.

How can I choose the right straw for my business?

Buyers often ask for “the best straw.” But I ask back: “Best for what drinks, and what service model?” Then I match options.

The best straw depends on drink type, service time, cleaning ability, branding goals, and compliance needs in your target markets.

A simple B2B decision matrix

I like decision matrices because they reduce debate.

| Business Type | Typical Drinks | What matters most | Best match (my view) |

|---|---|---|---|

| Coffee shops | Hot latte, iced coffee | Heat + mouthfeel + no taste | Bamboo fiber (8–10mm) |

| Bubble tea shops | Milk tea + pearls | Strength + large diameter | Bamboo fiber (10–12mm) |

| Hotels and buffets | Mixed drinks | Premium feel + reliable supply | Bamboo fiber + reusable bamboo for VIP |

| Takeaway platforms | High volume | Consistency + packaging efficiency | Bamboo fiber bulk packs |

| Fine dining | Premium branding | Aesthetics + story | Reusable bamboo sets + fiber backup |

| Schools and institutions | Volume + safety | Food-grade + compliance | Bamboo fiber, simple specs |

The three pain points I solve in every project

I see the same objections. So I answer them directly.

1) “It costs more than plastic.”

Yes, the unit price is often higher. But the total business cost can be lower. If you avoid penalties, you avoid big losses. If you reduce complaints, you reduce refunds. And if your brand can charge a small premium, you recover the difference fast.

2) “Paper is too soft.”

This is a daily reality. Paper can work for water in a short window. But many drinks need more time. So I treat paper as a “low-risk, low-performance” option. It can fit some menus. But it cannot fit all.

3) “I worry about supply stability.”

This is why factory capability matters. I prefer partners with stable lines and clear QA. I also prefer suppliers who can ship reliably and pack well.

Why I keep the story simple

In B2B, a simple story sells better than a complex story. I help buyers say: “We switched to plastic-free bamboo fiber straws.” That is easy. That is clean. And that is easy to defend under questions.

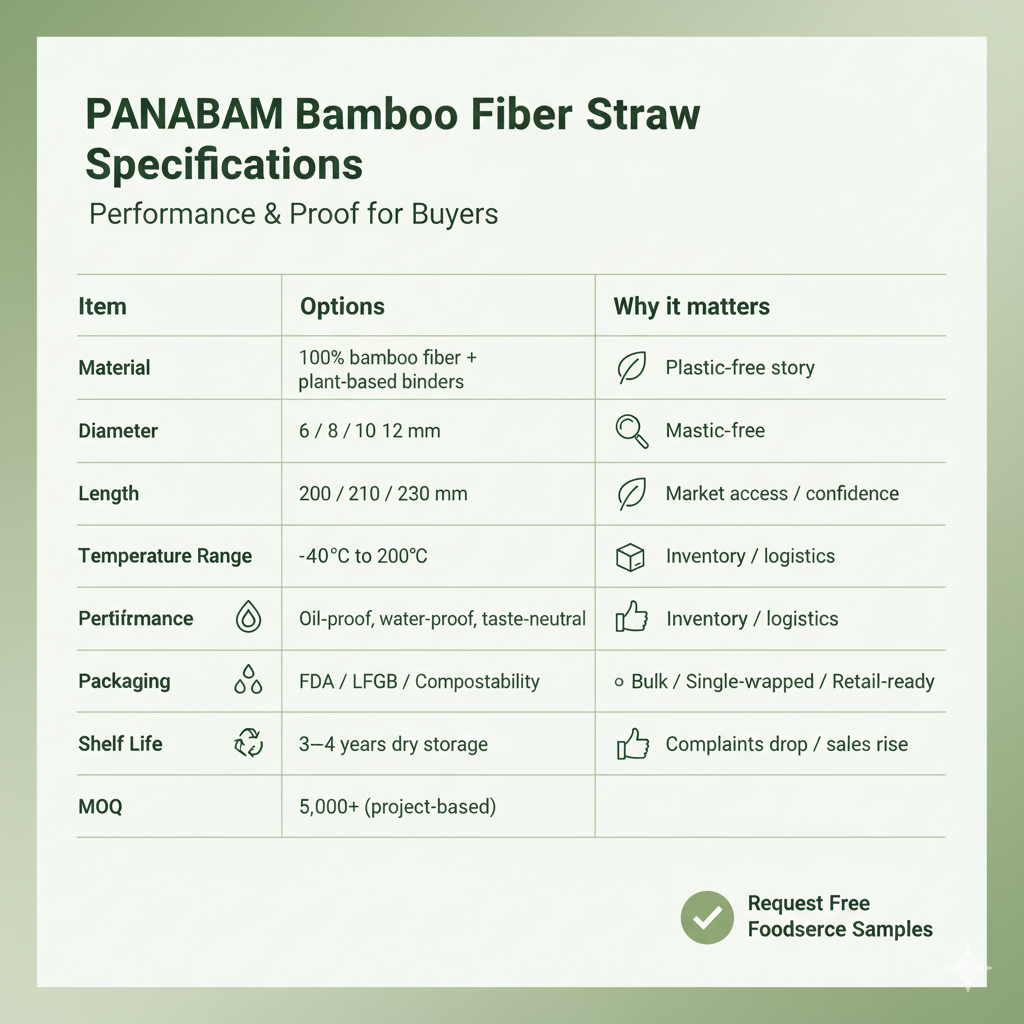

What are PANABAM bamboo fiber straw specifications that matter for buyers?

Buyers want two things at the same time: performance and proof. So I provide both, and I keep the specs clear.

PANABAM bamboo fiber straws use bamboo fiber with plant-based binders, offer multiple diameters, support hot and cold drinks, and align with food-contact and compostability documentation needs.

Specs are strong assets because they match transactional intent. When a buyer searches “compostable straws bulk” or “biodegradable straws wholesale,” they want real parameters. They also want to feel that I understand operations. So I present specs in a clean format.

Core specifications (buyer-friendly)

| Item | Options | Why it matters |

|---|---|---|

| Material | 100% bamboo fiber + plant-based binders | Plastic-free story, stable performance |

| Diameter | 6 / 8 / 10 / 12 mm | Espresso vs latte vs pearls vs soda |

| Length | 200 / 210 / 230 mm | Cup sizes and lid styles |

| Temperature range | -40°C to 200°C | Frozen drinks and hot drinks |

| Performance | Oil-proof, water-proof, taste-neutral | Complaints drop, repeat sales rise |

| Certifications (typical needs) | FDA / LFGB / compostability documentation | Market access and buyer confidence |

| Packaging | Bulk / single-wrapped / retail-ready | Hygiene and channel fit |

| Shelf life | 3–4 years dry storage | Inventory planning and lower waste |

| MOQ | Often starts around 5,000 (project-based) | Feasible for wholesalers and brands |

What I add beyond the table

I also explain how we reduce sourcing risk. PANABAM is not only a seller. We are a factory with long-term production lines and large-scale output. So we can keep quality stable. And we can also optimize packaging to reduce shipping damage and cost. That was a key point in the Canadian feedback. They tested quality, but they also compared shipping. So I treat logistics as part of product value.

If you want samples for real testing, I use a clear next step: Request Free Foodservice Samples →

What are the top questions people ask about plastic straw alternatives?

People Also Ask questions are not noise. So I answer them clearly, and I keep the language simple.

The most asked questions focus on the best non-plastic straw, restaurant legality of paper straws, eco-friendliness, health safety, and material comparisons like bamboo vs plastic or silicone vs plastic.

What is the best alternative to plastic straws?

I usually recommend bamboo fiber for foodservice because it balances performance, plastic-free positioning, and compostable end-of-life. But I still match it to the drink menu and the service model.

Can restaurants still use paper straws?

In many places, yes. But customers often complain because paper softens fast. So paper can be a short-term choice. But it can also create hidden costs through bad reviews and re-serves.

What is the most eco-friendly straw?

For scale, I focus on “no microplastics, plastic-free, and real compostability.” Bamboo fiber can fit this goal. Reusable options can also be very eco-friendly if a business can wash and manage losses.

Are bamboo straws better than plastic?

Yes, because bamboo breaks down far faster in natural conditions, and it avoids microplastic pollution. But buyers still need to confirm food-contact safety and coating details.

What is the healthiest material for straws?

I focus on food-grade documentation, taste neutrality, and chemical avoidance. Bamboo fiber that is certified for food contact and made without BPA, PFAS, and plasticizers can be a strong choice.

Is silicone safer than plastic?

Silicone can be safe in use. But it is not biodegradable. So it fits reusable programs, not single-use compostable programs.

A final buyer CTA that stays practical

If you want a plastic-ban compliant solution for bulk supply, I keep the action simple: Get Plastic Ban Compliant Today →

In conclusion

Bamboo fiber straws balance compliance, performance, and trust, so they beat paper and reduce risk versus market-rejected alternatives.

Shmily Lee

Hi there! I’m Shmily, a proud mom to an amazing boy and the manager of PANABAM. We’ve been producing eco-friendly bamboo tableware that’s both sustainable and high-quality. I’m passionate about helping businesses embrace greener solutions. Let’s connect and create a more sustainable future together!