I see many food-service buyers feel stress as plastic bans grow and costs rise.

Biodegradable disposable plates are single-use plates that break down through natural microbial activity into water, CO₂, and biomass under proper conditions.

I want you to stay with me because this guide will show clear facts you can use right away.

Why are food-service businesses moving away from plastic plates?

Many buyers feel pressure because plastic bans reduce options fast.

Food-service companies move away from plastic plates because plastic waste lasts for centuries, breaks into microplastics, and fails new laws in many countries. Biodegradable plates meet sustainability goals and support compliance.

Because laws keep changing fast, and customers keep asking for greener choices. I also see fear because many buyers worry that switching from cheap plastic will hurt margins. I understand this fear because I worked with many wholesalers who saw their cost per unit rise after plastic bans.

I want to explain this shift step by step so it feels simple and clear.

Market Pressure

Plastic plates face stronger restrictions across the US, EU, UK, Australia, and many Asian markets. Buyers must adjust because these rules affect everything from restaurants to government procurement. This pressure pushes teams to upgrade tableware even when they do not feel ready.

Customer Values

More diners ask for eco packaging. Many stores tell me customers compare brands by small details like plates and cutlery. This change creates a new form of trust.

Comparison Table: Plastic vs Biodegradable Plates

| Feature | Plastic Plates | Biodegradable Plates |

|---|---|---|

| End-of-life | Centuries | Months (under proper conditions) |

| Law compliance | Often fails | Usually passes |

| Customer perception | Low trust | High trust |

| Environmental risk | Microplastics | No microplastics |

What are biodegradable disposable plates?

Many buyers feel confused because the word “biodegradable” gets used too loosely.

Biodegradable disposable plates are plates made from natural or bio-based materials that break down through microorganisms into water, CO₂, and biomass under controlled composting conditions.

I want to break this down because I know many buyers think biodegradable means “breaks down anywhere.” This is not true, and this misunderstanding leads to wrong choices and buyer frustration. I had a distributor once tell me he felt misled because his previous supplier told him a product was biodegradable, but it only degraded in industrial composting.

How Biodegradation Works

Microorganisms break down organic fibers when heat, moisture, and oxygen exist in the right balance. This process is slow in cold or dry places, but it is fast in composting facilities. So I help buyers understand that the environment matters more than the label.

Biodegradable vs Plastic

Plastic plates do not break down. They stay in landfills for centuries and often release microplastics. Biodegradable plates break down into harmless components. This difference helps companies follow local rules.

Quick Table: Breakdown Process

| Stage | What Happens |

|---|---|

| Microbe contact | Fibers begin to soften |

| Heat + moisture | Structure breaks down |

| CO₂ release | Natural carbon cycle |

| Biomass | Turns into soil-like material |

What materials are used for biodegradable plates?

Many buyers worry they cannot tell real biodegradable materials from fake “eco-looking” ones.

Biodegradable plates use natural fibers like bagasse, paper pulp, PLA, palm leaf, wheat straw, or bamboo fiber. Performance and sustainability vary by material.

I talk with many clients who tell me they get confused because products look similar. A white plate may look “eco,” but it may still have PE or PLA coating. I want to show a simple way to see the differences. When I explain this to buyers at trade shows, I often see relief because they finally feel a clear line between materials.

Types of Materials

Each material has its own strengths. Bagasse is soft but cheap. Paper pulp is common but often needs coating. PLA is plant-based but still behaves like plastic in real use. Palm leaf looks natural but has limited supply. Wheat straw is light and dry. Bamboo fiber is stronger and more stable.

Material Table

| Material | Pros | Cons |

|---|---|---|

| Bagasse | Cheap, common | Soft, may leak |

| Paper pulp | Easy to shape | Needs coating |

| PLA | Bio-based | Not home compostable |

| Palm leaf | Natural look | Limited supply |

| Wheat straw | Light | Low strength |

| Bamboo fiber | Strong, heat-resistant | Higher unit cost |

Why Looks Mislead

Many plates use coatings that buyers cannot see. These coatings may not degrade. So I remind buyers to ask for proof and test reports.

What is the difference between biodegradable, compostable, and recyclable?

Buyers often feel confused because these three words sound similar but mean different things.

Biodegradable plates break down naturally, compostable plates break down under controlled composting conditions, and recyclable plates can be reprocessed into new materials.

I explain these terms many times at exhibitions because most buyers want clear definitions they can use with their teams and customers. Many countries mix these words, so I always share one simple rule: biodegradable is the broadest category, compostable is a stricter and safer version of biodegradable, and recyclable belongs to a different system.

Biodegradable vs. Compostable: A Simple Side-by-Side Comparison

| Term | How It Breaks Down | Conditions Needed | What Remains After Breakdown | Key Notes |

|---|---|---|---|---|

| Biodegradable | Breaks down naturally with microbes | Natural conditions; timing varies a lot | May leave residue, not always toxin-free | All compostables are biodegradable, but not all biodegradable items are compostable |

| Compostable | Breaks down fully into water, CO₂, and biomass | Requires composting conditions (heat, moisture, microbes) | Leaves no toxic residue, produces nutrient-rich compost | Look for certified compostable standards (BPI, EN 13432, AS 4736) |

The terms biodegradable and compostable are often used as if they are the same, but they are not. Biodegradable plates break down with the help of microbes, but the speed and the leftover materials can be uncertain. Compostable plates break down faster under controlled composting conditions and leave no toxic residue. This is why compostable products are safer and more reliable for food-service buyers who want clear compliance. When buyers are not sure which claim is true, I always suggest choosing certified compostable plates, because certification proves the plate can break down fully and safely.

Industrial vs Home Composting

Industrial composting uses high heat and airflow. Many “compostable” plates only break down there. Home composting is cooler and slower. Bamboo fiber plates handle both better than PLA.

Certification Matters

I ask buyers to request BPI, EN13432, OK compost, or FDA food-contact reports. These documents protect their brand.

Comparison Table

| Term | Meaning | Testing |

|---|---|---|

| Biodegradable | Breaks down naturally | No universal standard |

| Compostable | Breaks down in compost facility | EN13432, BPI |

| Recyclable | Can be reprocessed | Material-specific |

What performance do food-service buyers need?

Many buyers feel stress because some eco plates are weak, soft, or leak.

Food-service plates need heat resistance, oil resistance, leak-proof structure, and strong rigidity to handle real meals.

I see many buyers switch suppliers because their first “eco” plates fail real use tests. I remember Zack telling me his team used double-plating because bagasse plates got soft with hot pasta. This problem is common. I want to show the real standards buyers should check because performance affects cost more than unit price.

Real Use Conditions

Food plates face hot meals, oily dishes, sauces, and long serving times. Many cheap plates bend when wet. This leads to complaints.

Why Performance Matters

A strong plate reduces waste, lowers complaint rates, and protects the brand. Many buyers save money by avoiding double-plating even if unit price is higher.

Performance Table

| Feature | Low-Grade Materials | Bamboo Fiber |

|---|---|---|

| Heat resistance | Weak | Strong |

| Oil resistance | Needs coating | Natural |

| Rigidity | Soft | Very firm |

| Leak-proof | Poor | Stable |

Why do bamboo fiber plates stand out?

Many buyers want a plate that feels premium but still stays eco and safe.

Bamboo fiber plates stand out because they are strong, heat-resistant, oil-resistant, and fully biodegradable without coatings or plastic.

I enjoy explaining bamboo fiber because it solves most issues buyers complain about. I work inside a bamboo fiber factory, so I see every step from bamboo planting to final molded products. I always like to share stories from our production line because many buyers think bamboo fiber is similar to paper. It is not. I want to show how the material and process help performance.

How Bamboo Fiber Plates Are Made

We grow and harvest bamboo, turn it into fiber, mix it into slurry, and shape it through high-pressure hot molding. This process creates plates with natural strength without plastic.

Key Advantages

Bamboo fiber is dense, stable, and heat-tolerant. It handles hot meals, oily recipes, and long serving times better than most fibers. It works without wax or PE coating. It also feels firm in the hand.

Table: Why Bamboo Fiber Wins

| Advantage | Why It Matters |

|---|---|

| High strength | Reduces double-plating |

| Natural oil resistance | No plastic or PFAS |

| Heat stability | Works for hot meals |

| Smooth texture | Premium experience |

What is the environmental impact of biodegradable plates?

Many buyers want to know if biodegradable plates truly help the planet.

Biodegradable plates reduce landfill burden, lower microplastic risk, and support a better carbon footprint when disposed of properly.

I want to look at the full life cycle because many buyers only look at what happens after disposal. I talk about sourcing, production, transport, and end-of-life because each stage carries impact. I once explained this to a wholesaler who thought all biodegradable plates had the same footprint. He felt surprised when he learned bamboo grows faster and needs less water than trees.

Raw Materials

Bamboo grows fast and needs no replanting. Sugarcane bagasse comes from waste fiber. Paper pulp needs tree harvesting. This affects sustainability.

Production

Energy use changes by material. Some factories use old machines. We use automated lines that save power.

End-of-Life

Biodegradable plates break down cleanly while plastic stays forever. But if biodegradable plates go to landfills without oxygen, they break down slowly. So disposal matters.

Environmental Table

| Stage | Plastic | Biodegradable |

|---|---|---|

| Raw material | Fossil fuel | Renewable |

| Breakdown | No | Yes |

| Microplastics | High | None |

| Carbon footprint | High | Lower |

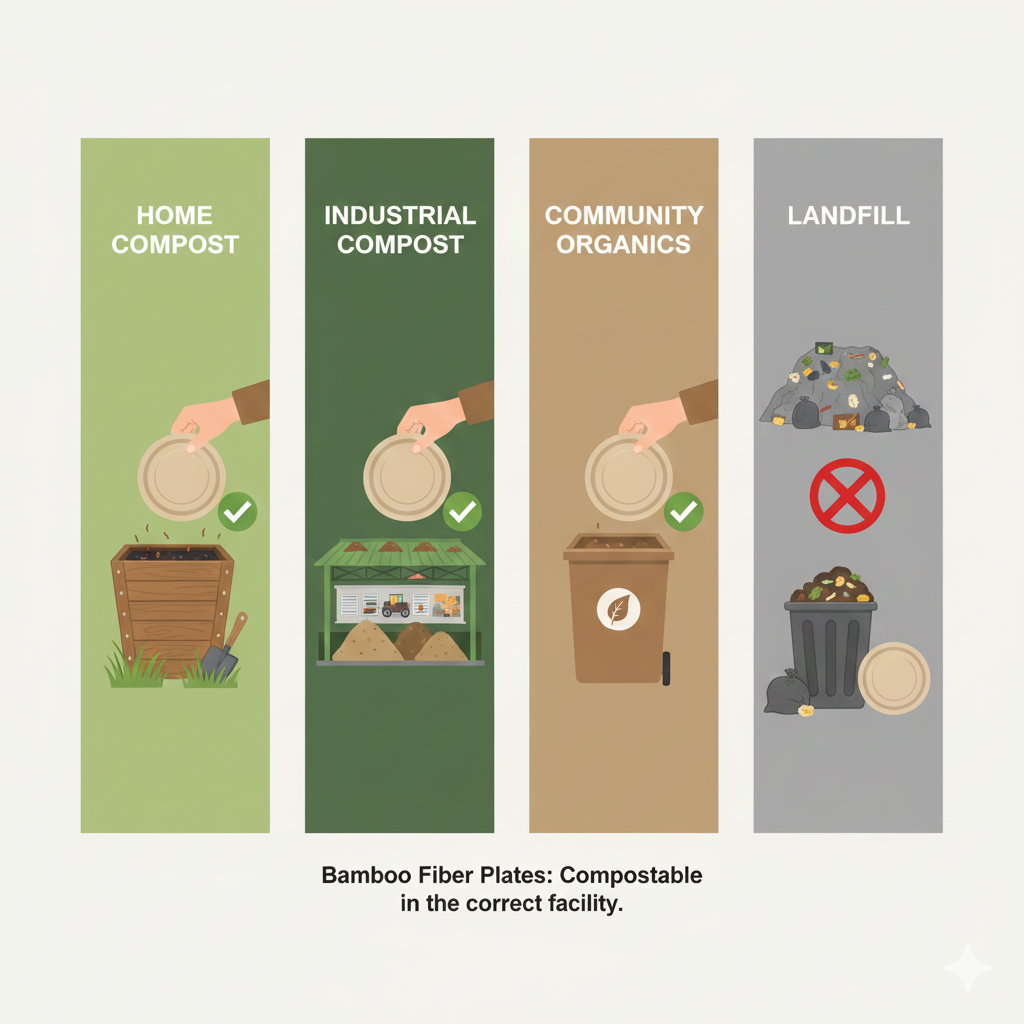

How should businesses dispose of biodegradable plates?

Many buyers feel confused about disposal rules in each country.

Biodegradable plates can go to home compost, commercial compost, or community organics programs when available.

I explain disposal often because many buyers worry that wrong disposal could harm their ESG goals. I also see confusion inside restaurants because staff members do not know which bin to use. I want to show simple steps any business can use.

Home Compost

Some natural fiber plates break down in home compost. Bamboo fiber handles this well.

Commercial Compost

Many cities run high-heat compost systems. These systems process plates faster.

If Compost Is Not Available

I suggest keeping plates separate from heavy plastics. Landfill disposal slows breakdown, but it still avoids microplastics.

Disposal Options

| Option | Speed | Notes |

|---|---|---|

| Home compost | Slow | Good for natural fibers |

| Industrial compost | Fast | Needs facility |

| Landfill | Slow | Still better than plastic |

| Community organics | Medium | Location-based |

What environmental benefits can biodegradable plates bring to your brand?

Many brands feel pressure because customers want proof of real action, not claims.

Biodegradable plates support ESG goals, meet plastic-ban rules, and help brands show visible sustainability values.

I talk with many brand owners who want their customers to feel the value of sustainability. I always tell them that customers judge with their eyes and hands. When a customer holds a bamboo fiber plate, the brand story becomes real. I want to show how biodegradable plates can connect with a brand image. I also share this with buyers who need to explain choices to their management teams.

ESG and CSR

ESG policies push companies to reduce plastic. Biodegradable plates support these goals. Many companies use them in offices, events, or cafeterias.

Marketing Impact

A clean, natural-looking plate tells a story without words. Customers often post photos of eco-friendly packaging. This creates free marketing.

Greenwashing Risks

Brands must use accurate claims. Certifications help reduce risk.

Brand Benefits

| Benefit | Why It Matters |

|---|---|

| Better brand trust | Customers feel the value |

| ESG alignment | Meets internal goals |

| Plastic-ban compliance | Reduces legal risk |

| Clear product story | Easy to communicate |

What is the cost and value difference between biodegradable and plastic plates?

Many buyers worry biodegradable plates look expensive at first glance.

Biodegradable plates cost more per unit but save money by reducing complaints, improving brand value, and removing hidden costs like double-plating.

I talk with many buyers about cost because cost affects every order. I explain that cost thinking and value thinking are different. I share simple examples from clients who switched to bamboo fiber plates and improved their average ticket price in dine-in and catering. I want to show how performance and brand image change customer behavior.

Hidden Costs of Cheap Plates

Plastic plates face bans. Bagasse plates may need double-plating. Complaints hurt the brand. These hidden costs rise over time.

Value Thinking

A strong, premium-looking plate makes meals look better. Customers trust the brand more. Many restaurants raise prices slightly because the presentation looks better.

Cost vs Value

| Item | Plastic | Bamboo Fiber |

|---|---|---|

| Unit price | Low | Higher |

| Complaint rate | Higher | Lower |

| Presentation | Basic | Premium |

| Customer trust | Medium | High |

| Real cost | Higher long term | Stable |

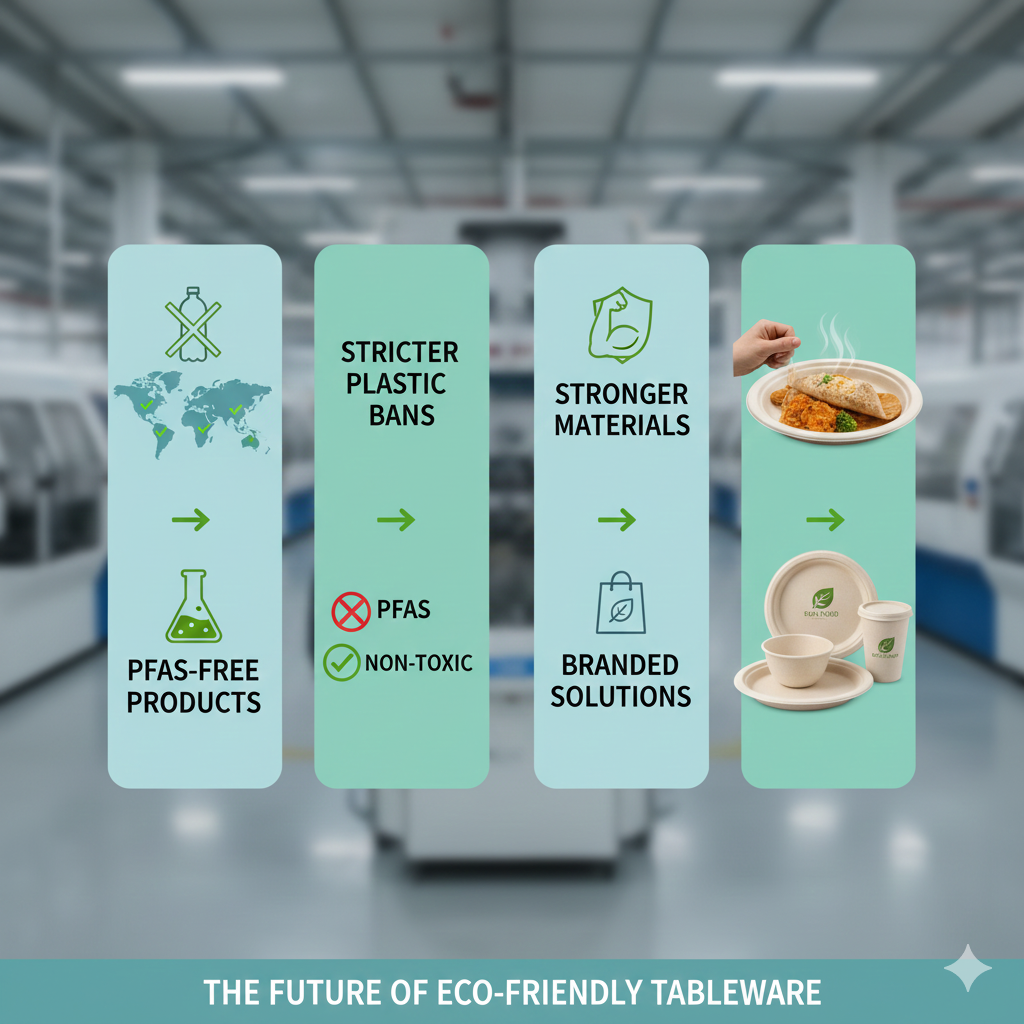

What are the future trends in biodegradable tableware?

Many buyers want to know where the market is going next.

Future trends include stricter plastic bans, PFAS-free requirements, stronger molded fiber materials, and more branded biodegradable solutions.

I follow this market closely because we run the automated bamboo fiber production line. I talk with buyers in the US, EU, Japan, and Australia, and I see the same trend everywhere. I want to show what will shape the next 5–10 years.

Regulatory Trends

More bans target single-use plastics. New laws restrict PFAS. Many countries require compostable certification.

Technology

Factories upgrade to coating-free oil resistance. Automation increases consistency. Materials get stronger.

Market Demand

QSR chains, airlines, and events want branded biodegradable sets. They want trays, lids, bowls, and plates that tell a unified story.

Trend Summary

| Trend | Impact |

|---|---|

| PFAS ban | Safer products |

| Automation | Better quality |

| Branding | Higher margin |

| New materials | Better performance |

What should buyers look for when sourcing biodegradable plates?

Many buyers feel unsure because suppliers vary widely.

Buyers should check product tests, certifications, MOQ, lead time, customization, logistics, and after-sales support.

I help many new buyers who feel overwhelmed by choices on Alibaba or trade shows. They tell me every supplier says “high quality” but shows no proof. So I guide them to focus on testing, stability, and service. I want buyers to feel confident when they compare suppliers.

Key Tests

Oil resistance, heat resistance, water absorption, rigidity, load bearing.

Certifications

FDA, LFGB, BPI, EN13432, FSC.

Sourcing Checklist

MOQs, customization, delivery time, sample process, packaging strength, damage rate.

Sourcing Criteria

| Item | Why It Matters |

|---|---|

| Tests | Avoid weak products |

| Certifications | Protects brand |

| MOQ | Fits budget |

| Lead time | Supports planning |

| Logistics | Reduces damage |

| Support | Solves problems |

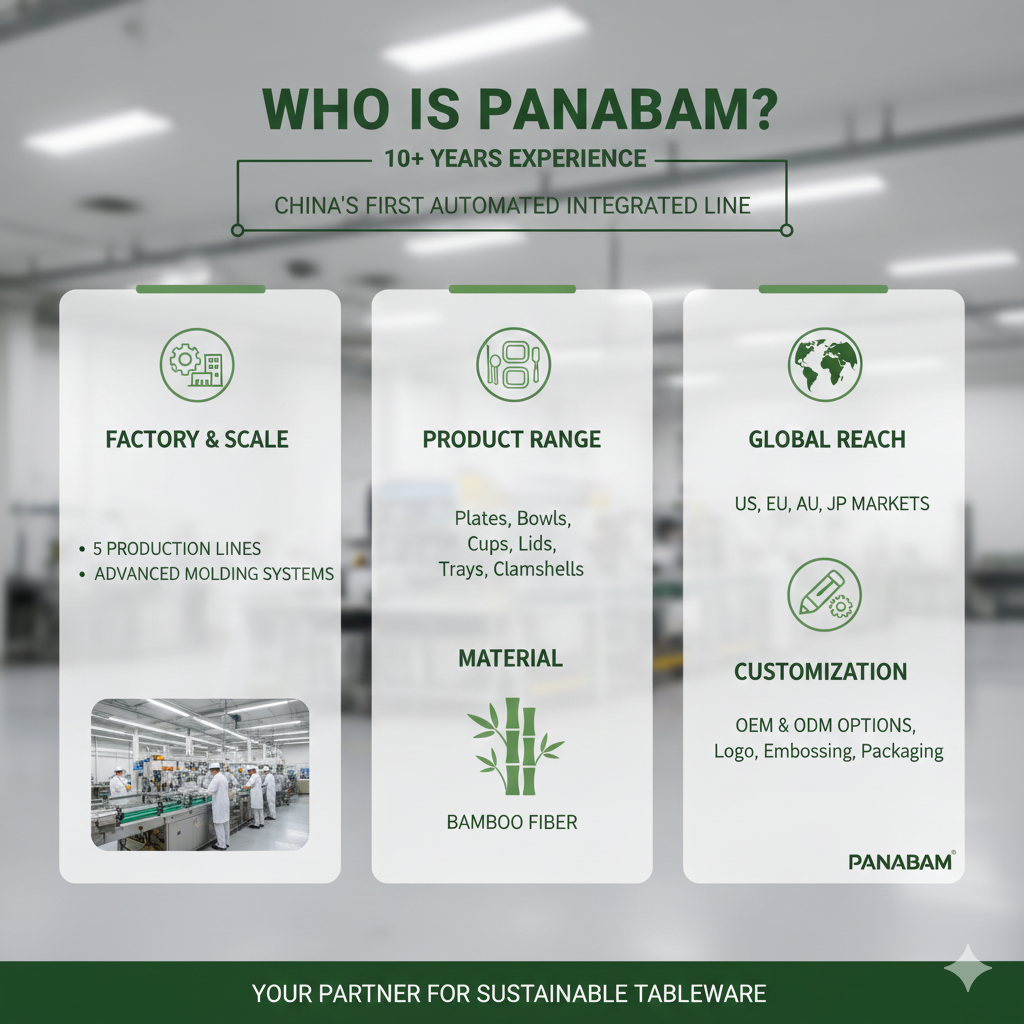

Who is PANABAM?

Many buyers want a stable supplier that can scale.

PANABAM is a bamboo fiber tableware manufacturer in China with automated production lines and 10+ years of experience.

I share our story with pride because I see how hard our team works every day. We run China’s first automated integrated line for bamboo fiber tableware. We control bamboo planting, fiber processing, and production. This control helps us keep quality stable. I talk with buyers from the US, UK, Japan, Australia, and Europe who want strong, certified products.

Factory Scale

We run five production lines and advanced molding systems. We support long-term programs.

Product Range

Plates, bowls, cups, lids, trays, clamshells.

Customization

Logo, embossing, packaging, size, shape.

PANABAM Overview

| Feature | Detail |

|---|---|

| Production lines | 5 |

| Market | US, EU, AU, JP |

| Material | Bamboo fiber |

| Options | OEM & ODM |

What are the use cases for biodegradable plates across different industries?

Many buyers want to understand real use scenarios.

Biodegradable plates work for restaurants, cafés, catering, events, weddings, festivals, retail, distributors, airlines, and hotels.

I work with many types of clients, so I see different needs. Restaurants want strength. Caterers want premium plating. Retailers want private label. Distributors need stable supply. I want to show how bamboo fiber plates fit these needs.

Restaurants

Plates handle hot and oily food. No double-plating.

Catering

Premium look for weddings and events.

Retailers

Private-label packaging for eco aisles.

Use Cases

| Client Type | Needs | Bamboo Fiber Fit |

|---|---|---|

| Restaurants | Strength | Very strong |

| Events | Look | Premium |

| Retail | Branding | Flexible |

| Airlines | Weight | Light |

How does PANABAM solve common buyer pain points?

Many buyers switch suppliers because they face product failure, delays, or inconsistent quality.

PANABAM offers strong plates, stable supply, certifications, and support for branding and marketing content.

I listen to buyers who complain about splinters, breakage, delays, and mixed quality. I want them to feel safe when they choose us. Our automated lines reduce human error. Our QC team checks every batch.

Performance

No double-plating. Strong and heat-stable.

Supply Stability

We ship to the US, EU, UK, Japan, Australia.

Support

Samples, marketing tools, co-branding help.

Pain Point Solutions

| Pain Point | Solution |

|---|---|

| Weak plates | Bamboo fiber |

| Delays | Automated production |

| No proof | Certifications |

| Low brand value | Premium design |

How to start sourcing from PANABAM?

Many buyers do not know the first step.

Buyers can start by sending an inquiry, requesting samples, testing products, receiving quotes, placing trial orders, and scaling up.

I help many new buyers start simple. I want sourcing to feel clear and fast. When buyers share usage, specs, target price, and required certifications, I prepare accurate samples and quotes.

Steps

Inquiry → Samples → Testing → Quotation → Trial Order → Scale.

What to Prepare

Food type, size, order volume, packaging needs, certification needs.

Sourcing Steps

| Step | Action |

|---|---|

| 1 | Send inquiry |

| 2 | Request samples |

| 3 | Test in real use |

| 4 | Receive quote |

| 5 | Trial order |

| 6 | Long-term plan |

You can contact me through:

Website: www.panabam.com

Email: 1@panabam.com

Name: Shmily Lee

FAQ About Biodegradable Disposable Plates?

Many buyers want simple answers to common questions.

Biodegradable plates break down in months under composting conditions and work for most hot, oily, and saucy foods.

I answer these questions every day. I want answers to feel simple.

How long do they take to break down?

A few months in compost. Slower in landfills.

Are they microwave safe?

Bamboo fiber works well in microwave and freezer use.

Will they get soft?

Bamboo fiber stays firm with soup or greasy food.

Do they replace plastic?

Yes, they meet most local rules.

Conclusion

Biodegradable plates offer strong performance, safer materials, and real environmental value when buyers choose trusted suppliers.

Shmily Lee

Hi there! I’m Shmily, a proud mom to an amazing boy and the manager of PANABAM. We’ve been producing eco-friendly bamboo tableware that’s both sustainable and high-quality. I’m passionate about helping businesses embrace greener solutions. Let’s connect and create a more sustainable future together!