Plastic pollution has become a pressing global issue. As countries implement plastic bans, the demand for alternatives has soared. Pulp molding is emerging as a sustainable solution.

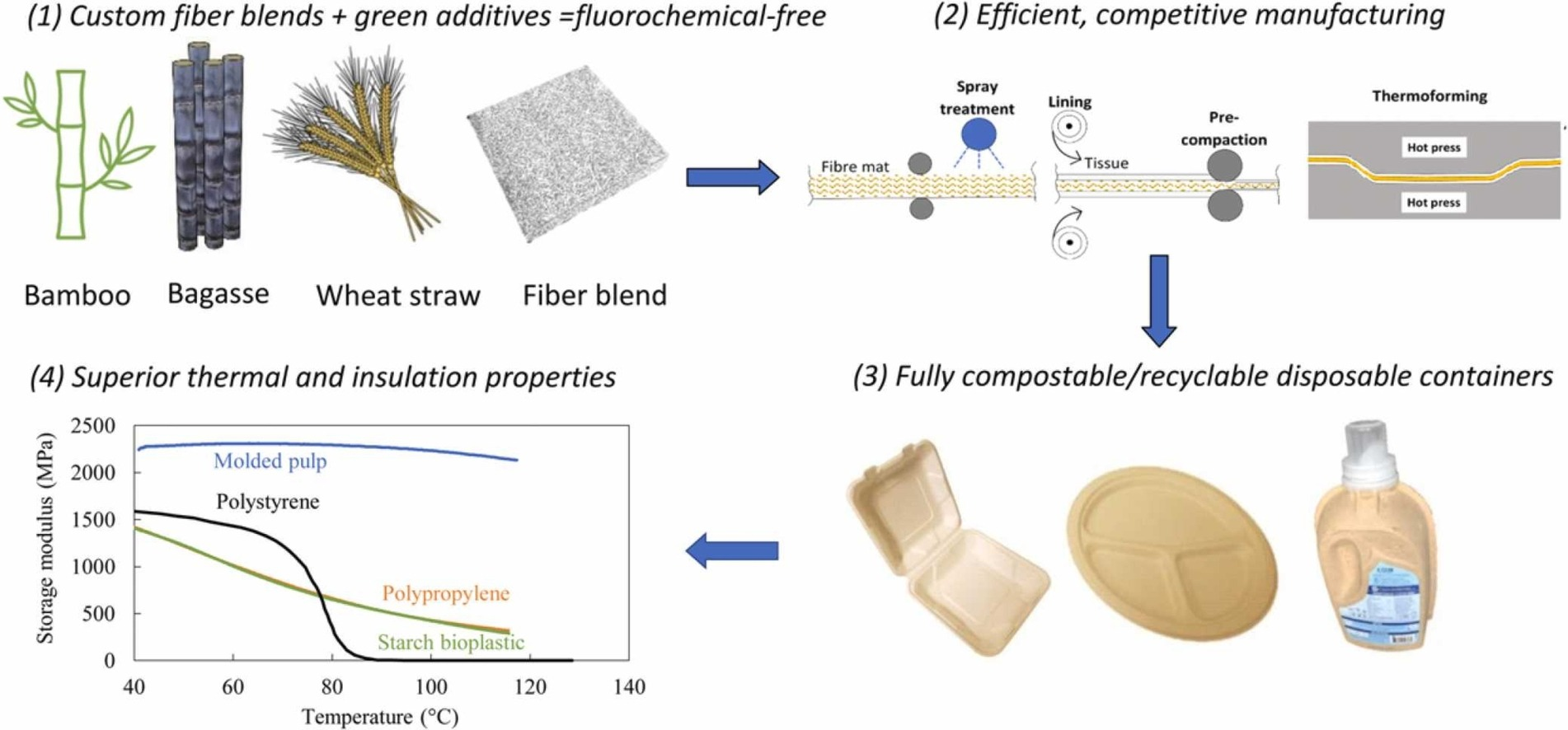

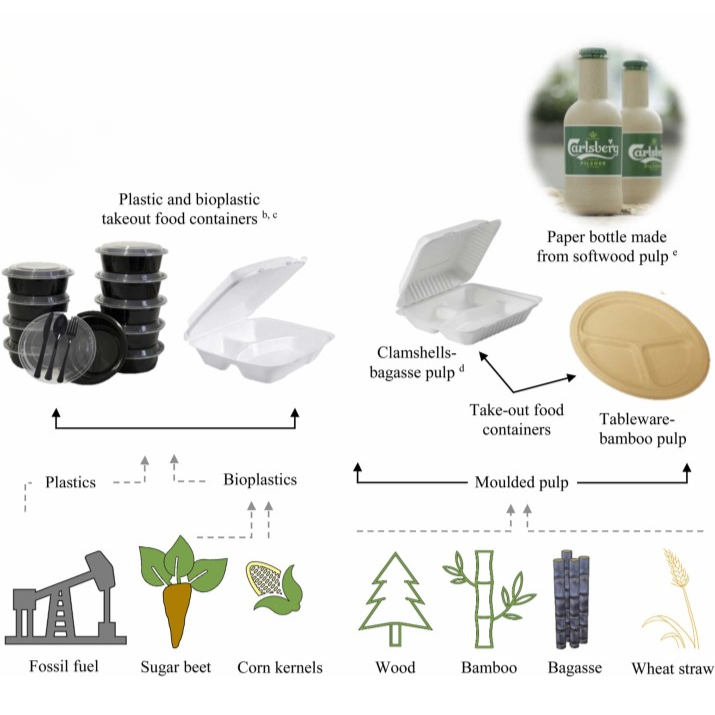

Pulp molding, made from natural fibers like bamboo pulp, offers a biodegradable, cost-effective alternative to plastic. It also supports the circular economy.

Continue reading to explore the value of pulp molding and its role in building a more sustainable future.

1. Introduction: The Rise of Pulp Molding?

As the world becomes more aware of environmental damage, governments are enforcing stricter plastic bans. This shift is creating a massive opportunity for businesses to adopt eco-friendly alternatives. The surge in demand for green packaging and sustainable products is undeniable. Consumers, especially in the food service industry, are increasingly seeking alternatives to plastic, with pulp molding rising to the occasion.

Pulp molding is gaining traction as an eco-friendly alternative to plastic, driven by global plastic bans and consumer demand for sustainable solutions.

At Panabam, we are proud to contribute to this change. As a bamboo pulp tableware manufacturer, we understand the responsibility of offering products that not only meet the needs of today but also support a greener future. Our fully automated production lines ensure that we deliver quality bamboo pulp products that support the shift toward a circular economy.

2. Pulp Molding as a Plastic Alternative?

Pulp molding, made from plant fibers like bamboo pulp and bagasse, provides a strong, biodegradable alternative to plastic. These materials decompose quickly, typically within three months in natural environments. This makes pulp molding an ideal solution in regions with plastic bans, particularly in the food delivery and catering sectors.

Pulp molding is a biodegradable, cost-effective alternative to plastic, making it perfect for industries affected by plastic bans, such as food delivery.

The Advantages of Pulp Molding Over Plastic

Pulp molding offers significant advantages over plastic. First, it is made from renewable resources, such as bamboo, which decomposes within a few months, unlike plastic that can take hundreds of years to break down. This quick degradation is vital for reducing landfill waste. Additionally, pulp molding is ideal for disposable products like food containers and tableware, which require frequent use and disposal.

Another advantage is the cost-effectiveness of pulp molding. While traditional plastic is cheap to produce, it comes with long-term environmental costs. In contrast, pulp molding may have slightly higher production costs, but its biodegradability and sustainable production methods make it a more responsible choice in the long run.

Overcoming Paper Product Limitations

Traditional paper products often face challenges like poor resistance to water, oil, or heat. However, recent advancements in pulp molding technology have significantly improved the performance of these materials. They now offer better water and oil resistance, making them suitable for a broader range of applications. This innovation has allowed pulp molding to replace plastic in many areas, from food packaging to tableware, particularly in the food service industry.

| Material | Degradation Time | Cost Comparison | Liquid Resistance |

|---|---|---|---|

| Pulp Molding | ~3 months | Low | High |

| PLA | ~6 months | Moderate | Moderate |

| Traditional Plastic | 100-500 years | Low | High |

3. Pulp Molding as a Carrier of the Circular Economy?

Pulp molding does not just replace plastic—it also plays a crucial role in the circular economy. By utilizing agricultural waste such as bamboo and bagasse, pulp molding contributes to resource recycling and reduces the need for virgin materials. Furthermore, when the products decompose, they return nutrients to the soil, completing the cycle.

Pulp molding supports the circular economy by utilizing agricultural waste and reducing carbon emissions in production.

How Pulp Molding Supports a Sustainable Economy

The circular economy focuses on resource reuse, reducing waste, and limiting environmental impact. Pulp molding exemplifies these principles by using agricultural byproducts that would otherwise go to waste. Bamboo, for instance, is a fast-growing plant that requires minimal resources, making it an ideal raw material. The production process for pulp molding generates lower carbon emissions compared to other materials, such as PLA, making it a more sustainable option for businesses seeking to reduce their environmental footprint.

Moreover, once pulp molding products reach the end of their life cycle, they naturally break down and enrich the soil, contributing to the growth of new plants. This creates a circular flow of resources, where nothing is wasted, and everything contributes to the ecosystem.

Low Carbon Emissions in Production

The production of pulp molding products is more energy-efficient than that of plastic or chemically synthesized materials like PLA. This is due to the natural resources used and the lower energy required in processing. The bamboo and other plant fibers used in pulp molding have a much lower carbon footprint than traditional plastic production, making it a better choice for businesses aiming to reduce their carbon emissions.

4. Comparison with Other Biodegradable Materials?

When comparing pulp molding with other biodegradable materials, like PLA, pulp molding offers advantages in terms of decomposition time, environmental impact, and cost. PLA, although biodegradable, requires specific conditions for decomposition and takes longer to break down. In contrast, pulp molding decomposes naturally under a wide range of conditions, and its production process is less resource-intensive.

Pulp molding outperforms PLA and other biodegradable materials in terms of decomposition, environmental impact, and cost-efficiency.

Pulp Molding vs. PLA and Traditional Plastics

PLA is often marketed as a biodegradable alternative to plastic, but it requires industrial composting facilities to break down effectively. Pulp molding, on the other hand, decomposes naturally in a variety of environments. This makes it a better solution for single-use applications, especially in areas where composting infrastructure is lacking.

Moreover, the production of PLA is energy-intensive and generates higher carbon emissions compared to pulp molding. Pulp molding, by using agricultural waste, minimizes environmental damage while offering a cost-effective and biodegradable solution.

| Material | Degradation Time | Production Energy | Environmental Impact |

|---|---|---|---|

| Pulp Molding | ~3 months | Low | Low |

| PLA | ~1 year | High | Moderate |

| Traditional Plastic | 100-500 years | High | Very High |

5. Industry Status and Future Trends?

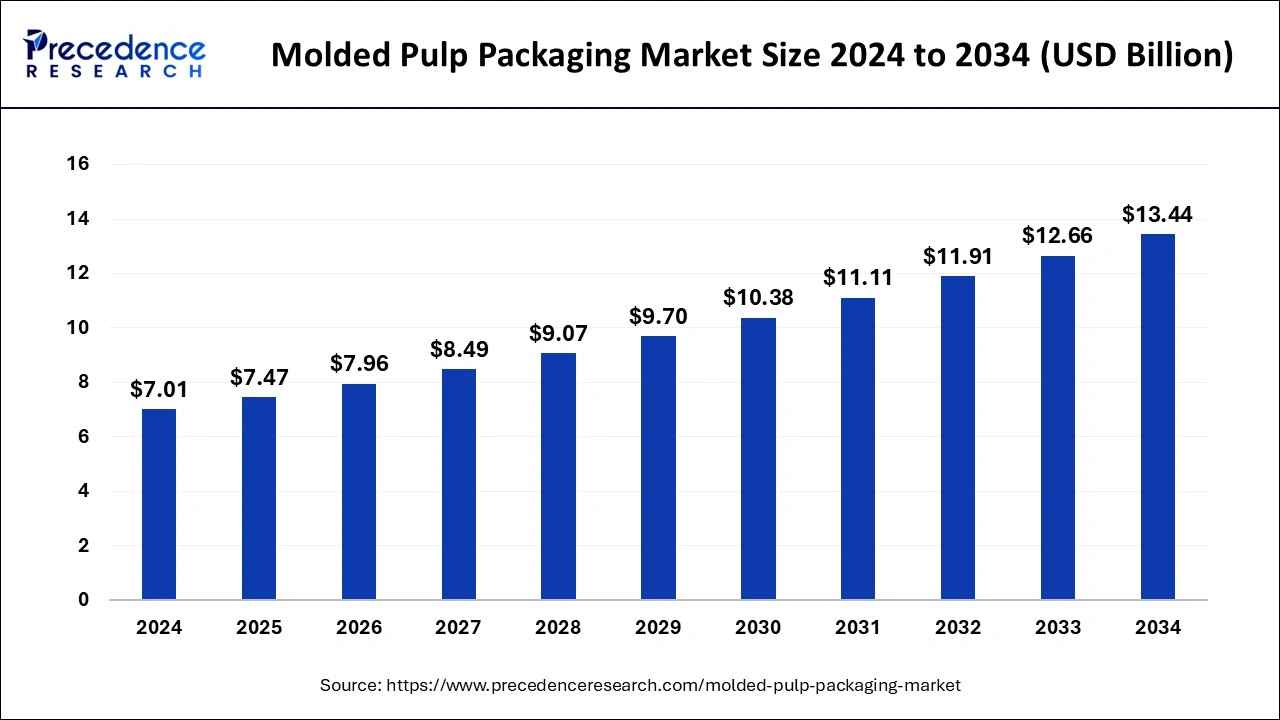

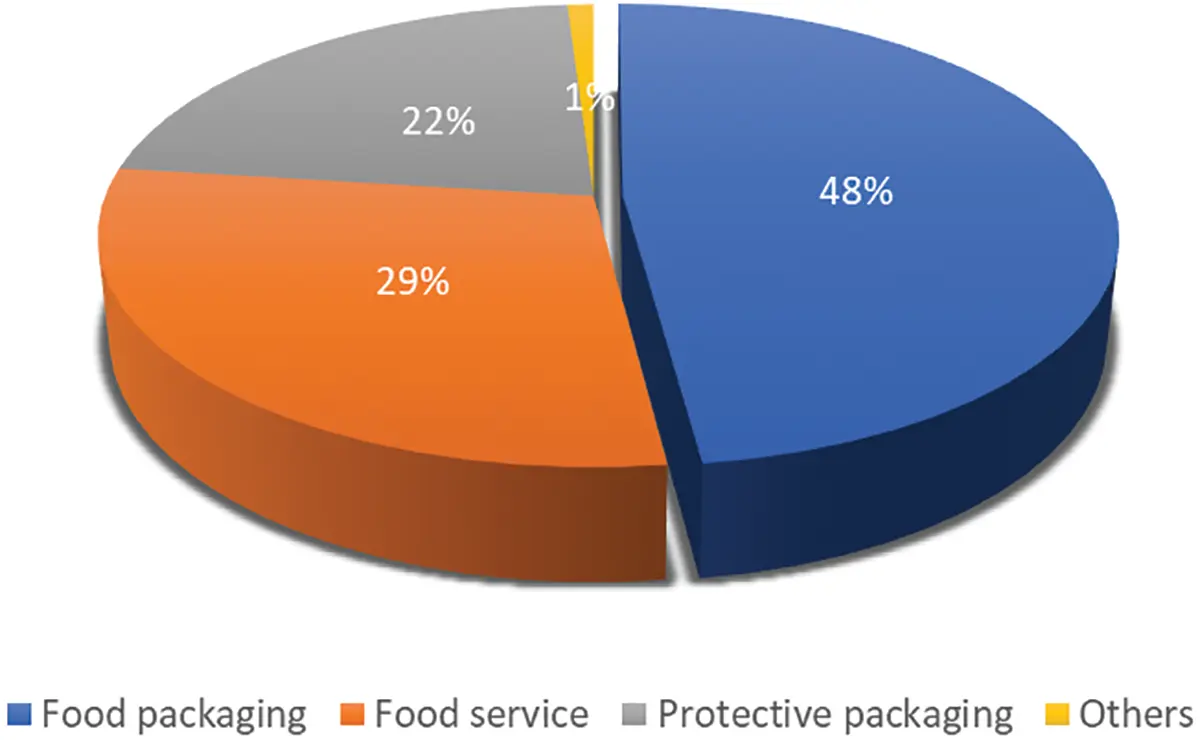

The market for biodegradable products like pulp molding is growing rapidly, particularly in the food delivery sector. As the demand for eco-friendly packaging continues to rise, companies are focusing on improving manufacturing processes to keep up with the demand. The food delivery industry, in particular, represents a huge opportunity for businesses that offer sustainable alternatives.

With increasing demand and technological advancements, the pulp molding industry is set for massive growth, especially in food delivery.

Technological Advancements and Industry Growth

Pulp molding technology is evolving, with improvements in production processes and material performance. Automated production lines, like those at Panabam, enable manufacturers to meet the growing demand for eco-friendly products. These innovations not only improve the quality of pulp molding products but also streamline production, reducing costs and increasing efficiency.

The industry is also benefiting from stronger policy support. Governments worldwide are implementing stricter regulations on plastic use, driving the adoption of sustainable alternatives. As more businesses turn to pulp molding, the industry is expected to grow at a rapid pace, with the food service and delivery sectors leading the way.

6. Panabam’s Commitment and Vision?

At Panabam, we are dedicated to promoting sustainability through our bamboo pulp tableware. Our innovative production methods ensure that we deliver high-quality products that align with global sustainability goals. As we continue to innovate, we aim to help our clients transition to more sustainable practices while contributing to the circular economy.

Panabam’s commitment to sustainability drives our innovation in bamboo pulp tableware, helping businesses achieve their green transformation.

Our Vision for a Green Future

Panabam’s dedication to environmental responsibility is at the core of everything we do. We are constantly innovating to improve our products and reduce our environmental impact. By focusing on bamboo pulp, we are not only offering a biodegradable solution to plastic but also helping to drive a larger movement towards sustainability.

In the future, we plan to expand our product line and explore new ways to improve the performance and sustainability of our products. Our goal is to make it easier for businesses to adopt eco-friendly practices while supporting the growth of the circular economy.

7. Conclusion

Pulp molding offers a dual value: it’s both a plastic alternative and a key player in the circular economy. By choosing eco-friendly materials, we can all contribute to a sustainable future.

Ann

Hi, I’m Ann, and with over 5 years of experience in the foodservice industry, I’ve had the pleasure of working with restaurants and catering businesses to develop eco-friendly, tailored solutions that help you thrive in today’s green economy. I’m passionate about sustainability and committed to providing high-quality products that align with your values.

If you’re looking to make the switch to eco-friendly, sustainable tableware, I’m here to help! Reach out today, and let’s explore how we can support your business’s goals while contributing to a healthier planet.